Flottweg Centrifuges for Olive Oil Production

Ancient olive oil making was done exclusively by hand. Later, simple machines such as mechanical presses and pan grinders driven by human or animal power were used. The separation of oil, fruit water, and pulp was done by static settling. Nowadays, olive oil is manufactured in a process using modern machinery. In the early 1970s, Flottweg was one of the first companies to introduce decanter centrifuges to the olive oil production process, replacing the existing hydraulic press method. At Flottweg, constant development has since been conducted in order to improve the decanter performance in terms of oil yield, throughput capacity, and machine service life. Since then, Flottweg has delivered thousands of decanters and Tricanters® to all olive oil producing countries in the world.

Our machines for olive oil extraction

How olive oil production works:

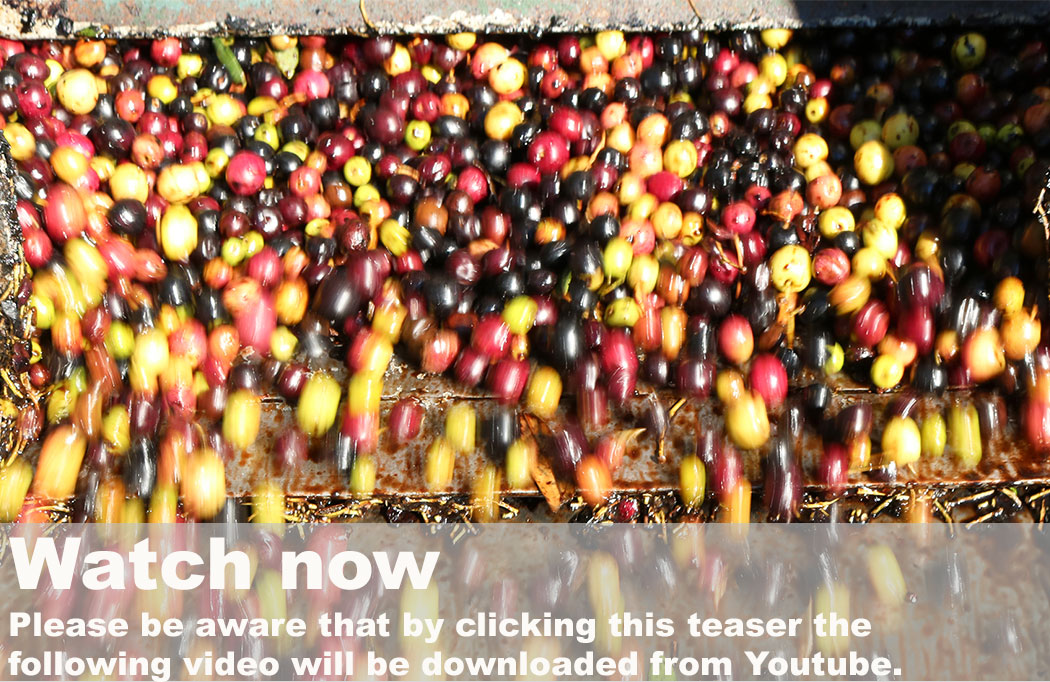

Prior to processing, olives are cleaned to remove leaves, bits of branches, stones, soil, and other impurities. Then a mash is produced by crushing the olives and pits.

This mash is conveyed to the malaxer or kneading mill. Malaxing, releases the oil from the oil cells encapsulating it. The malaxing procedure is critical for oil yield and quality. The influencing parameters are holding time and temperature.

Then the mash is pumped to the Flottweg decanter (2-phase) or Tricanter® (3-phase) for separation. In the Tricanter® (3-phase), the mash is separated into oil, fruit water and solids, i.e. olive stone debris and pulp. On the way to the Tricanter®, dilution water is added to the feed in order to fluidize the mash. In the 2-phase process, the mash is separated into oil as liquid phase and solid phase (pomace) consisting of olive stone debris, pulp and fruit water.

The oil from the Flottweg decanter or Tricanter® is then polished using a disc stack centrifuge, which separates the residual amount of water and solid impurities to obtain clean oil.

A certain amount of residual oil remains in the pomace from the extraction. In order to recover this oil, the pomace undergoes a second extraction stage.

Greater profit thanks to the 2nd extraction phase in olive oil manufacture

Flottweg decanters and Tricanters® are optimized for maximum oil yield. Nevertheless, the technical yield in oil during the first extraction is typically in the range about 85% and more, due to the olive variety, operation temperature and other process parameters. This is true for 2- as well as 3-phase operation.

The pomace after first extraction contains a certain amount of residual oil which is worth recovering. Depending on the efficiency of the first extraction, i.e. oil concentration in the pomace, up to 50 % of the oil can be recovered (depending on the incoming product temperature) via a second mechanical extraction stage, thus significantly increasing the gross oil yield. The second extraction can be performed normally in 2- or 3-phase operation without having to add water.

Sample process combining the 1st and 2nd extraction phases.

Sample process combining the 1st and 2nd extraction phases.

Your advantages in manufacturing and extracting olive oil:

When using Flottweg machines in manufacturing and extracting olive oil, you benefit from very low fresh water consumption and reduced wastewater.

Production costs and raw material prices are rising. To help our customers continue offering competitive prices, Flottweg maximizes the yields and reduces the energy costs to get first-class olive oil.

Flottweg machines can be operated 24/7, are made of high-quality materials, and offer numerous practical features.

Even the best machine needs servicing from time to time. Flottweg has subsidiaries and representatives all over the world that have an ear for your concerns.

Flottweg separation technology for olive oil production at Virgen del Voto S L

Over 90% of the world’s olives are harvested in the Mediterranean region. One of the foremost areas is the Spanish region of Andalusia. The Cordoba area is where the majority of Spanish olives are grown and processed. One of those companies is Virgen del Voto S L in the town of Bujalance. Between 1.2 and 1.5 million kilograms of olives are processed on site.

Contact us now and get advice from our experts.