We make your success our responsibility

Flottweg’s innovative separation technology is driven by pioneering techniques that support and drive change in the world. Our products are the key to sustainable and economically efficient processes. This includes:

- Using raw materials more efficiently

- Maximizing yield

- Reducing process costs

- Finding sustainable solutions for your processes

- Saving resources, such as water and energy

Whether your goal is the last drop during apple juice production or to ensure the optimum taste of plant-based milk: Our mission at Flottweg is to provide you with the best possible support on your path to success.

As a separation technology specialist, we can help you find individual solutions to make your processes sustainable, effective, and economical. Flottweg has almost 70 years of expertise and experience and is ready to help you find highly specific solutions for your company's application area.

Manufacture of plant-based milk alternatives

Our decanter centrifuges process milk from a wide variety of plant and grain types, such as soy, oats, almonds or pulses. Flottweg's centrifuges ensure that the plant-based milk alternative has an optimal taste and pleasant palatability. You also profit from maximum machine performance, easy operation, low service costs, and efficient machine cleaning.

Manufacture of fruit and vegetable juices

Cost-effective extraction of fruit juice and vegetable juices is not only characterized by excellent juice quality but also by a high yield of the raw material. The reduced operating, maintenance, and servicing requirements of our Flottweg separation technology also reduce the cost of operation. For an economical overall process, we offer the optimum solution for every step - from separating the solids from the mash and the subsequent extraction of the pomace to the separation of turbidity and the clarification of juices.

Manufacture of beer

Our industrial centrifuges extract the very last drop of beer so that hops and malt do not go to waste. Flottweg finds customized and holistic solutions for specific brewing processes. Flottweg’s highly efficient centrifuges meet the specific requirements of breweries and optimize processes holistically: for maximum yield, highest beer quality and reduction of side streams and waste water.

- Wort recovery

- Beer recovery of Beer from Spent Hops – Dry Hopping

- Recovery of beer from surplus yeast

- Beer Clarification

- Brewers grain processing and yeast dewatering

Instant Coffee Production

In the production of coffee and instant coffee, mechanical separation technology has a decisive influence on coffee quality and production efficiency. Flottweg decanters, the Tricanter®, belt presses and separators make it possible to extract the maximum yield from valuable coffee beans and ensure a cost-effective, high-quality coffee.

- Recovery of extracts from the extraction residues

- Clarification of the thin and thick extract

- Extract recovery from separator sludges

- Coffee oil extraction

Production of Wine

Flexible, reliable and easy-to-operate decanter centrifuges and separators from Flottweg help you to achieve the best possible results in must treatment and the production of wine. They enable efficient and gentle solid-liquid separation and thus contribute to a high yield and a high-quality end product.

Instant Tea and Tea Extract Production

Flottweg separators and decanters are used in the extraction of tea extract, the production of instant tea and the clarification of tea. Whether it is the optimal dewatering of tea leaves, the separation of the finest solids from instant tea products or the optimal clarification of tea: Flottweg decanter centrifuges and separators ensure gentle treatment of the tea and a high quality of the end product.

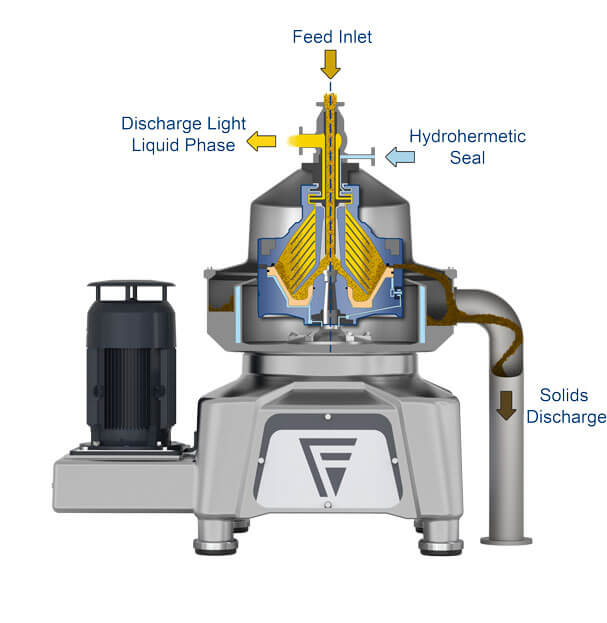

From algae harvesting to beer clarification and protein extraction: If you want to separate or purify liquids or remove ultra-fine particles you need powerful and robust separators. With their enormous centrifugal acceleration of up to over 12,000 g, Flottweg separators are real purification and clarification all-rounders - highest quality made in Germany.

Where decanter centrifuges reach their performance limits, the use of separators begins. Thanks to their high speeds, they are able to optimally process liquids. Clarifiers (2-phase separation), separate the finest solid particles from a liquid. Purification separator (3-phase separator), separate liquid phases of different densities, and simultaneous removal of solids.

Soft Shot® Flex – the quietest and most flexible discharge system on the market

- Minimal noise

- Any emptyingsequence is possible

- Variable, partial,and full discharge

- Speed-independent

- Increased dry matter content

Automation and control system – Intelligent Process Control

- Intuitive recipe management

- Completely automated

- Plug & Play

Flottweg Longlife Concept – Consistent design following our simple and smart approach

- Inlet system with non-contact seals

- Minimal number of wear parts

- Compact assemblies

- Efficient beltdrive

- Drive system with standard motor

- Safety & Solutions

- Hygienic design & CIP capability

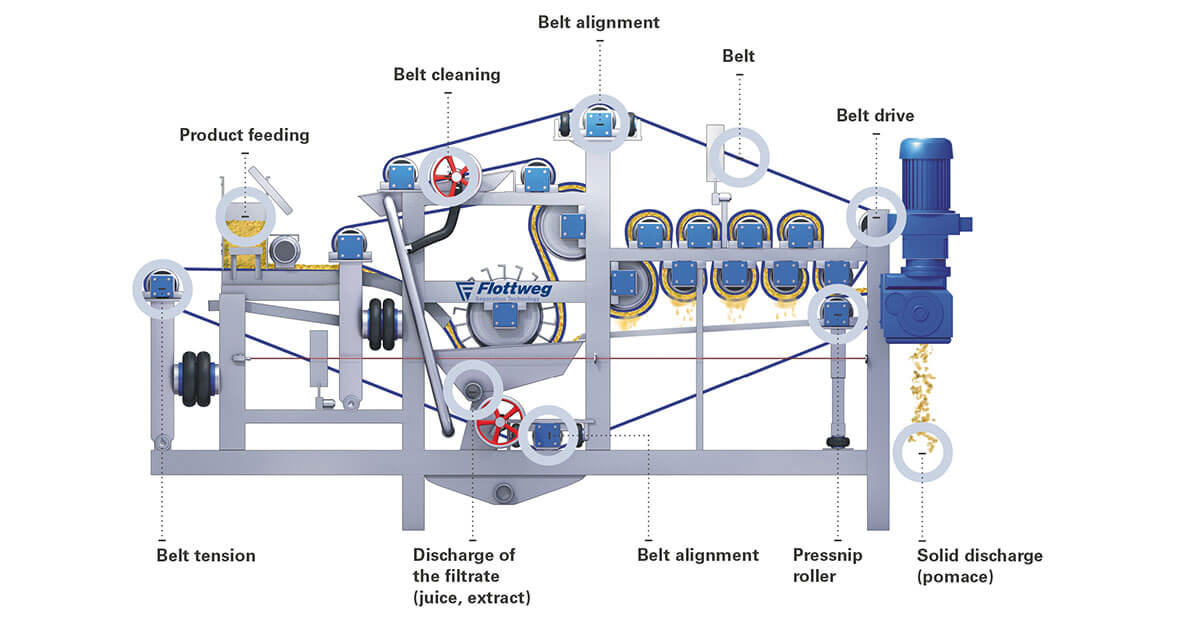

Anyone who wants to dewater pomace, mash or spent grains silage uses belt presses. They press the last residue out of the solids cake and are easy to maintain, clean and operate thanks to their easily accessible construction. Flottweg belt presses are robust, durable and powerful - quality made in Germany.

Excellent juice quality is essential when processing fruit or vegetables. In order to conserve the valuable ingredients during processing, the raw material must be processed quickly, reliably and hygienically. The Flottweg belt press masters these challenges effortlessly.

In the production of starch or vegetable milk alternatives, the solids should have as high a dry matter content as possible in order to reduce transport and drying costs. This is also easy for the Flottweg belt press.

The Flottweg belt press is usually part of an overall process. It is often combined with an upstream decanter centrifuge. Depending on the individual process, Flottweg will find the optimum solution and provide all-round support.

Flexible adaptation thanks to Flottweg Extraction System

- Coordinated press zones: Slow pressure increase allows gentle dewatering

- Flexible feeding system: Wide application of the solid cake, optimized by experience and trials

Hygienic design and easy cleaning

- Consistent use of stainless steel for superior hygiene

- Pneumatic system for belt tensioning and belt running control

- Open design for thorough cleaning

- Automatic CIP cleaning

Low cost concept for more efficiency

- Automated operation – one operator suffices

- Low operating and maintenance costs

- Reduced fresh water consumption

- Low energy consumption thanks to efficient drive motor

- Robust design for long life and 24/7 continuous operation

- Continuous work process with high throughflow

The belt press in action

More efficient juice extraction - The Flottweg belt press at Frankly Juice

Flottweg Belt Press for Apple Cider Production at Minard Farm Beverage Company

Frequently asked questions (FAQs)

Thanks to our machines' adaptability, we can find the right solution for almost any industry-specific separation task. Flottweg provides comprehensive support from project planning through to the design of complete process solutions, helping you to get the most out of your machine and to find the best solution for your company. It is important to us, with the help of our machines, to facilitate an economical, efficient and performance-oriented approach so that nothing stands in the way of your company's success.

In good conscience, we cannot give a one-size-fits-all answer to this question. This is because various criteria must be taken into account before your processes can run smoothly, efficiently, and sustainably. Because the proper plant and machine size are essential factors to your success, our experts can only answer this question once they have learned about and analyzed your process. However, what we can say for sure is that: Our machines are used in over 500 different fields of application around the world, and Flottweg’s solid/liquid separation functions as a key technology. With our knowledge and experience gained over 60 years, we can also work with you to find the right solution for your process. Get started on the path to success – contact us with your request today.

From the first consultation, through the purchasing decision, to commissioning and the operational phase: Flottweg is your experienced and reliable partner from start to finish. Our machines play an important role in many industries and processes - it is therefore all the more important to us that you can turn to us at any time with your concerns and that you can count on Flottweg as your partner. For this reason, we also offer you various services, such as tailored maintenance contracts, spare parts deliveries, and rental machines. Please feel free to contact us at any time if you have any questions or uncertainties regarding service.

Are you interested in gaining further information about your field of application, learning more about our industrial centrifuges or systems, or accessing a success story from one of our current customers? You can find a wealth of information about our machines and product lines, the diverse fields of application and various case studies on our website. There, you will also find further details on the topic of service, Flottweg’s process solutions and informative brochures. Our Flottweg YouTube channel also features a wide range of explanatory videos, animations, and video testimonials relating to our machines and application areas.

Should you have any questions or a special request, please feel free to contact one of our specialists at any time.