- High-performance decanter centrifuges for optimum solid-liquid separation

- 60+ years of experience in separation technology for your process success

- Continuous automatic operation with minimal maintenance and no filter consumption

Flottweg

Decanter Centrifuges

Separate Solids and Liquids Efficiently

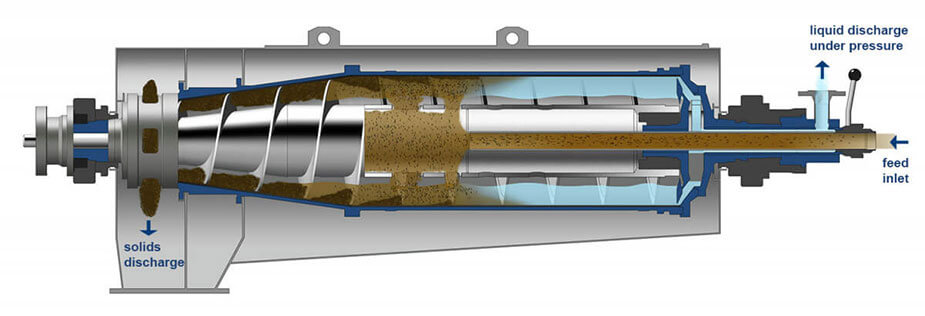

The Flottweg decanter - the most versatile solid bowl scroll centrifuge in mechanical separation technologyWhen solid/liquid mixtures with a high portion of solids need to be separated, decanter centrifuges are the solution of choice. In contrast to chamber filter presses, these solid shell scroll centrifuges or decanters operate continuously. High centrifugal forces separate the finely distributed solid particles from the suspension.

The modular design of our decanters makes them useful in a wide variety of industries throughout the world – from Australia to Zambia. The centrifuges are adapted optimally to the specific application. Applications range from sludge dewatering to classification or wet classification to the sorting of solids.

To obtain optimum results, solid bowl decanter centrifuges must be custom designed to suit specific separation processes.

Our Custom-Made Decanter Concepts

Custom-made designs have been created for different industries. The individual decanter series are based on uniform platforms that are adapted to customer needs using modular designs.

Flottweg Decanter Centrifuges for Best Separation Results

The efficiency of the overall process often lives or dies based on the performance of the centrifuge. Every Flottweg decanter centrifuge incorporates our experience from more than 60 years of centrifuge design and over 1,000 applications served. The basic functional principle of our decanters has been the same for a long time. The centrifugal acceleration separates the solid phase and one or two liquids from each another.

Because the sediment (solid phase) has a higher density, it collects on the wall of the bowl. The transport scroll moves the solid continuously to the outlet openings. The liquid phase(s) flows along the scroll.

Product features

Power

Our decanter centrifuges separate fine solids from a suspension and optimally clarify the separated liquid. The Simp Drive® concept and the adjustable impeller make it possible to adjust the residence time of the mixture in the decanter bowl during operation. If the conditions at the inlet change, the separation result and solids content in the discharge always remain constant. Custom-made decanter centrifuge solutions for the individual processes of our customers This is the only way to achieve optimum separation results.

- Separation of the finest solids from a suspension for an optimally clarified liquid phase (centrate)

- Consistent separation results, thanks to automatically regulated differential speed and adjustable impeller

- Custom-made solutions for the individual processes of our customers

Maintenance

Mechanical separation of liquids and solids with decanter centrifuges requires high forces. Abrasive materials or media with corrosive properties cause wear, abrasion and erosion. Flottweg offers a wide range of wear protection measures – always adapted to your application.

For all decanter components in contact with the product, Flottweg exclusively uses high-quality corrosion and acid resistant stainless steels. In addition there is a quality made in Germany. This makes our centrifuges particularly durable.

Depending on the requirements of our customers, we equip the decanter centrifuges with different lubrication systems. All lubrication systems allow the rotor bearings to be relubricated during operation.

The elimination of consumables (such as filter cloths and filter aids) additionally reduce maintenance and operating costs of our decanter centrifuges.

- Costs are reduced because only wear parts are replaced

- There are no consumables such as filter cloths, filter aids, etc.

- Longer service life of the decanter

- Various lubrication systems, e.g. automatic oil-air lubrication system for minimum oil consumption

Safety and security

The Flottweg Simp Drive® regulates the differential speed of the screw conveyor according to the load. If the differential speed is too low, there is a risk of blockage. With the correct setting, the system protects against overload and blockage. If the separation space is to be sealed against the atmosphere, Flottweg offers various sealing systems: atmospheric centrifuges, vapour-tight centrifuges, inert centrifuges. Various monitoring systems control vibration and speed. Critical operating conditions can thus be avoided and relevant safety standards complied with. Optionally, the storage temperature of the decanter centrifuge can also be monitored to prevent storage damage.

- Avoidance of emissions to the environment or contamination of the product from the environment by means of closed construction design

- protection against overload and blockage

- Vibration, speed and temperature monitoring possible

Operation

Flottweg decanter centrifuges are continuously operating industrial centrifuges. Modern automation options reduce the effort needed to operate the system to a minimum. This means that our decanter centrifuges, which are used in the pharmaceutical, biotechnology and food industries, can be easily integrated into CIP systems. Monitoring the individual functions and the interaction of the individual components plays an important role in the automation of processes. Our new control interface InGo is easy to understand and shows the most important parameters at a glance. InGo was awarded the German Design Award 2018 in recognition of its ease of use. Our Simp Control® safety and control module is also equipped with the InGo interface. Thanks to Simp Control®, we can guarantee our customers worldwide identical global machine performance and safety technology.

- minimal operator effort due to continuous and automatic operation

- Integration into CIP systems possible

- uniform and intuitive machine and system control

Innovation thanks to cooperation

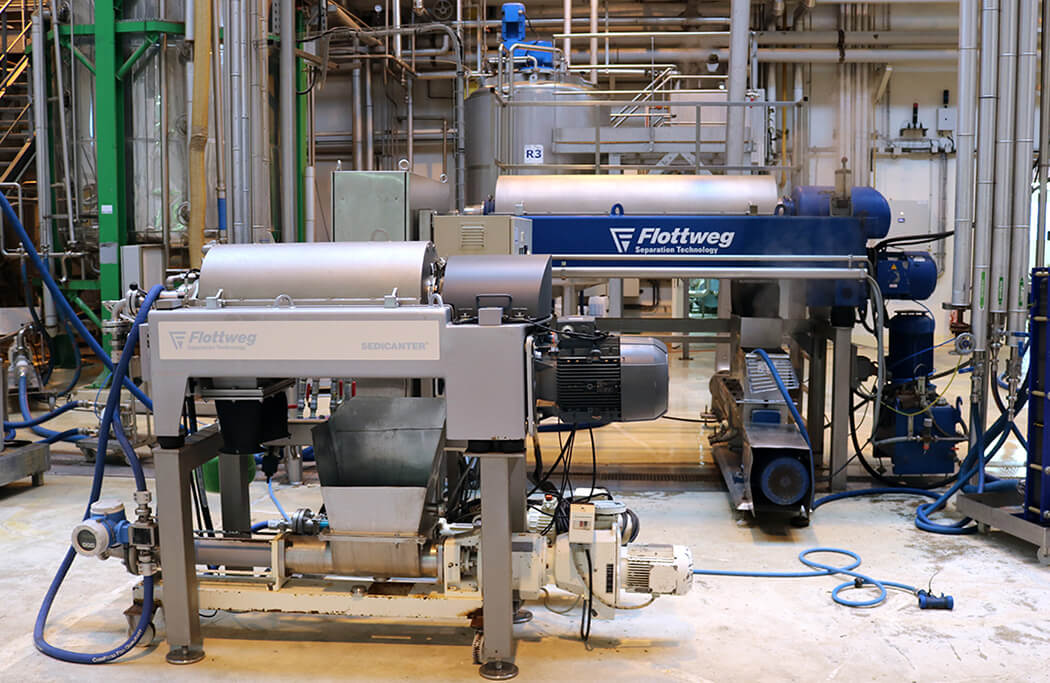

The cooperation between Flottweg and Extractis has been in place for over 15 years. Extractis is a technical institute specialized in the development of innovative products and processes and the extraction of plant biomass.

Three Flottweg machines are used in different processes: two decanter centrifuges and one Sedicanter®. Learn about the machines used and the many years of cooperation in this video.