- Transform waste cooking oil into valuable biofuel with German-engineered separation technology

- Three-phase separation in one step: Patented Tricanter® delivers optimal purity and efficiency

- 24/7 automated processing with expert support and proven durability

Extract valuable raw material from old deep fryer fat

Centrifuges for processing used cooking oil and waste oilThe food industry and cafeterias generate considerable quantities of used cooking oils. Used cooking oils are reprocessed by waste oil disposal companies. The recycled and processed used cooking oils serve as raw materials used in the production of biodiesel, hydrogenated vegetable oils (HVO) and technical greases. Good for the environment and the operator.

Waste fats, such as frying fat or the contents of grease separators, sometimes contain considerable amounts of undesirable foreign materials. These foreign materials need to be separated from the animal and plant fats. The Flottweg Tricanter® separates the unwanted solid particles from the fat in just one step.

Together with our customers, Flottweg works to develop individual complete solutions for the recycling of used cooking and frying oil. We partner with customers and provide advice throughout the entire process and also after purchase. Our decanters stand for durability, efficiency and high quality - manufactured exclusively in Germany.

Turning old into new ...

Biodiesel

The dependence on fossil fuels is reduced by using biodiesel. The valuable fuel can be extracted from waste fat among many other materials.

Flottweg technology makes it possible for you to create a recyclable material from used cooking oil in a particularly efficient and cost-effective manner.

Technical fats

Our machines need to be lubricated every now and then in order to run smoothly. Technical fats, which can also be produced from old fat with a decanter, are used to do this.

Hydrogenated vegetable oil

Vegetable fat can also be created from waste fat using the Flottweg Tricanter®. During the hydration process, moisture is removed from the vegetable oil to create hardened fat. This is then used, for example, in margarine, food spreads, or cookies.

Our machines for grease processing and waste oil recycling

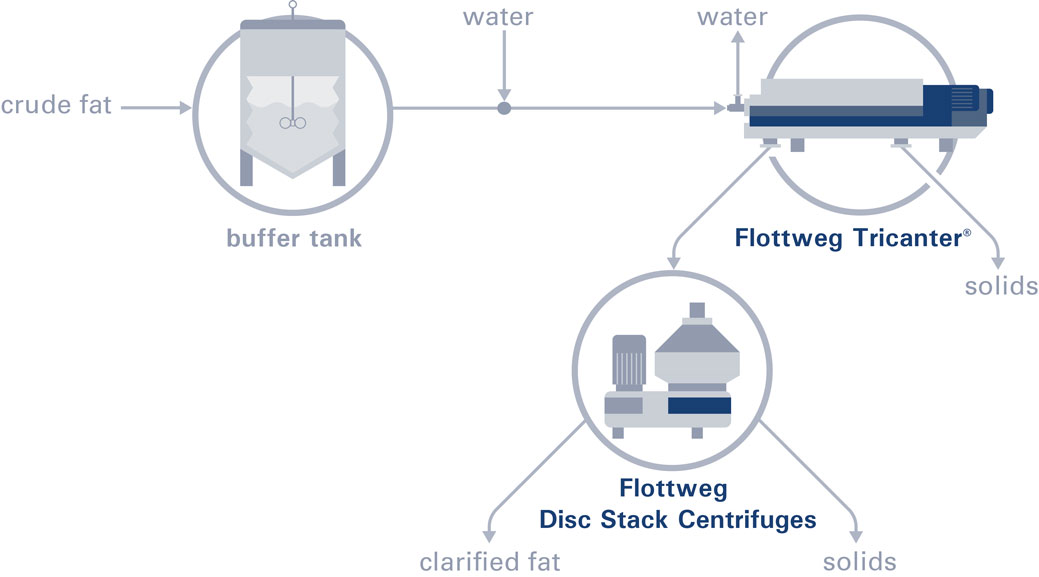

How is used fat processed? - The recycling process

Plant and animal fats, used cooking oils or the contents of grease traps are heated to the required processing temperature and fed to the 3-phase centrifuge.

The Flottweg Tricanter® separates water, oil and solid particles in just one step. Due to its robust design, the centrifuge easily manages the separation of solid particles of even different sizes and quantities.

Depending on the desired purity of the used fat, a separator can be installed downstream. This cleans the processed fat again and separates even the finest solid particles.

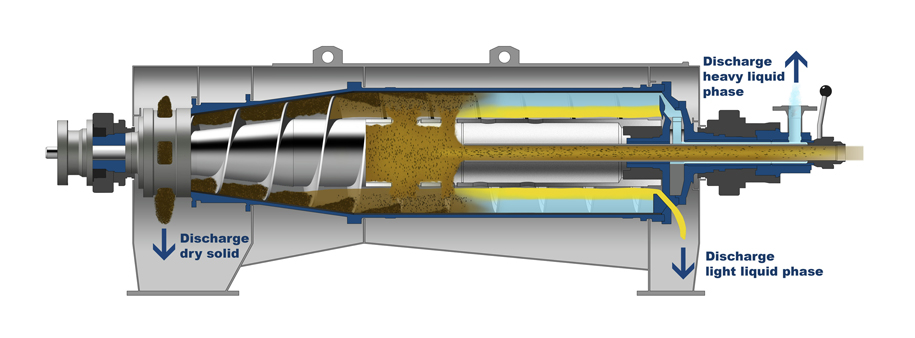

The Flottweg Tricanter® – unique three-phase separation

The first in the world and patented by Flottweg – the Tricanter®. It not only separates two phases, i.e. solid and liquid, from one another, but also manages to separate a third liquid phase. Thanks to 50 years of knowledge and success, the Flottweg Tricanter® can't be beat when it comes to efficiency and quality.

Adjustable impeller

The adjustable impeller ensures optimum separation resolution and therefore the best possible end product. It can be set automatically or manually as desired.

Materials

Depending on the requirements, components that come into contact with the product and wear protection for highly abrasive materials or use in the food industry are built to fit specific applications.

Housing flushing

Optimal cleaning of the housing is essential for hygienic applications. Housing flushing can thus can be fully incorporated into CIP processes.

Wear protection

Our Flottweg wear protection is optimally adjusted to your medium and process to ensures high machine availability.

Three-phase separation with the Tricanter® Flottweg

Three-phase separation with the Tricanter® Flottweg

Three-phase separation with the Tricanter® Flottweg

Customer benefits

Powerful Centrifuges

- Continuous processing of large quantities

- Consistent quality of end products

- Optimally cleaned fat

- Durable and low maintenance

Our patented Flottweg Tricanter® centrifuges are optimally designed for the purification of used cooking oils. The horizontal centrifuge can continuously process large quantities of waste oil and grease. Separation into purified fat, waste water and solids takes place in a single step. Flottweg's adjustable impeller allows the separation process to be adapted to the prevailing feed conditions. If the composition of the waste oil changes, the quality of the end products remains the same. This has a positive effect on the subsequent recycling processes.

Depending on the subsequent use, the processed fat can be clarified again with a separator. This separates even the finest solid particles from the fat and ensures optimally cleaned fat.

Thanks to "Made in Germany" and the use of reliable materials, our machines often last for over a decade.

Automated processes

- Intuitive operation thanks to Flottweg's Ingo

- Integration into existing processes

- Fully automatic control is possible

Our Flottweg decanters and separators can be easily integrated into existing processes or we can work with you to define a complete system for waste fat recycling. Thanks to Flottweg's Ingo, you always have all important parameters at a glance. The intuitive user interface simplifies the control of your process. Our centrifuges are designed for 24/7 operation. Fully automatic machine control. Our decanter centrifuges also react automatically to changing feed conditions. In the case of the separator, draining is also fully automatic.

A valuable raw material for the production of fuel and lubricating oil

- Raw material for the production of biodiesel

- Basis for Hydrogenated Vegetable Oils (HVO)

- Use for technical greases and lubricants

Used animal and vegetable cooking oils are collected from the food industry, cafeterias and restaurants in so-called waste oil drums and passed on to companies for the disposal of waste oil. The plants recycle the discarded cooking fats. The cleaned grease is used as a raw material for the production of fuel in the form of biodiesel or is used for hydrogenated vegetable oils (HVO) and technical greases as well as lubricating oil. The solid matter is often thermally recycled in biogas plants. The separated wastewater is free of harmful substances and can be fed to the municipal wastewater treatment plant.

A reliable partner in the processing of used cooking oil

- Individual complete solution

- Expert know-how and advice even after purchase

- On-site testing with our rental centrifuges

Throughout the engineering process, our experienced experts are available to advise our customers. Together with our customers, we develop individual complete solutions for an optimal overall process.

To be sure they will integrate into your processes, you can test our centrifuges as rental machines . You can be certain you've made the right choice with our decanters and separators.

“We decided to stick with Flottweg.”

A partner for life

Reno Rendering recycles oil and slaughterhouse by-products. Tanker trucks deliver fats, oils, and waste taken from grease traps in restaurants throughout northern Nevada to Reno Rendering for processing and recycling. Waste oil and grease from restaurant kitchens is also processed and then used as fuel in biodiesel plants.

The Flottweg Tricanter® separates the brown oil and grease from trap waste. Reno Rendering expressly emphasizes Flottweg’s excellent service: "We could have commissioned other companies to carry out maintenance, but we opted to stick with Flottweg for maintenance work, and it's all worked out very well.”

Thanks to Flottweg’s help, Reno Rendering was able to significantly extend the period between simple on-site maintenance and comprehensive disassembly of the machine in its own workshop.

Learn more about centrifuge performance and Flottweg support even after commissioning in this video.