Wear Protection From Flottweg

Decanter centrifuges from Flottweg are used in an extremely wide range of applications. This broad range of applications makes it necessary to provide the decanter centrifuge with adequate wear protection in order to adapt it to the particular conditions and requirements.

The Highest Level of Wear Protection

High forces are involved in the mechanical separation of liquids and solids using decanter centrifuges. Abrasive materials or media with corrosive properties give rise to wear, abrasion and degradation. Flottweg wear protection permits a long service life from the decanter centrifuge that is used. All wear protection parts can be exchanged or renewed, in order to minimise the maintenance costs when running abrasive products.

Flottweg Wear Protection for an Extremely Wide Range of Applications

Flottweg offers the following kinds of wear protection in order to reduce wear, degradation and abrasion to a minimum. Furthermore, highly diverse wear protection measures offer the opportunity to meet the requirements of all kinds of applications (e.g. foodstuffs sector).

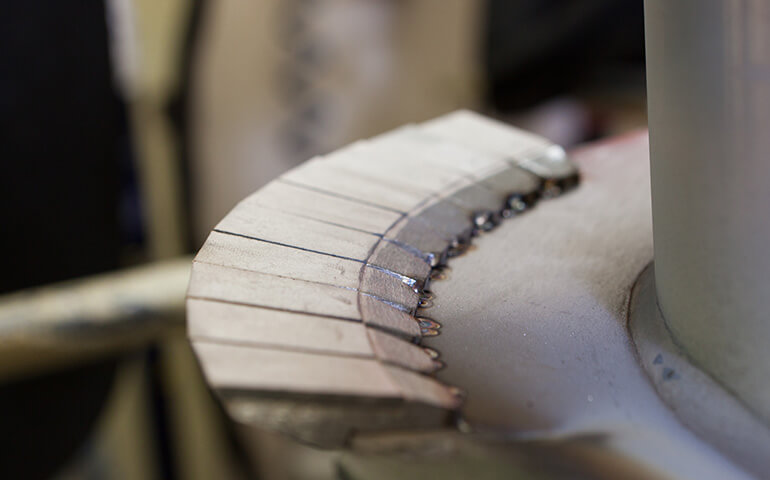

- Heat applied hard facing or thermal spray coatings with carbides

- Technical ceramics

- Sintered carbide plates

- Chilled cast iron

- 2-C systems with ceramic fill

Wear Protection from Flottweg and Its Advantages

- High resistance to wear of the decanter centrifuge

- Longer service life of the decanter

- Reduced costs, because only wearing parts are renewed

Wear protection from Flottweg - exchangeable bushes for the infeed and solids discharge (chilled cast iron or ceramic)