- High performance with up to 30% less energy consumption through innovative Recuvane® technology

- Maximum dewatering: Reduce your sludge volume by up to 8%

- 24/7 automated operation with smart controls for minimal personnel requirements

The Flottweg C-series

Wastewater Decanter

Full power with reduced energy consumption

Decanter centrifuges for sewage sludge and waste water applicationsThe demands on the quality and efficiency of sewage treatment plants are growing from year to year, not least due to rising energy and disposal costs. As a result, using decanters to dewater sludge means using state-of-the-art technology. The C-series decanters from Flottweg achieve high performance with reduced energy consumption.

Over the last five decades, Flottweg has acquired a wealth of experience in the field of sewage sludge thickening and dewatering.

We are aware of the special requirements of sewage treatment plants and the water industry. That is why we have developed our own decanter series exclusively for separation tasks in the sewage sludge sector and for the treatment drinking water. This is where our latest insights from the fields of mechanical engineering and manufacturing as well as measurement and control technology come together. A new generation of environmental centrifuges was created, characterized by the well-known Flottweg quality and reliability, as well as an optimal price-performance ratio.

Thanks to the interaction between a powerful and energy-efficient drive, the Flottweg Simp Drive®, and the continuously optimizing decanter geometry, Flottweg decanter centrifuges achieve separation values that are several percentage points higher than those of other models. The right machine is available for every plant size. The further ongoing development of the Flottweg decanter centrifuges guarantees optimum sludge thickening (OSE) and the highest possible sludge dewatering (HTS).

Application area: sewage sludge and waste water

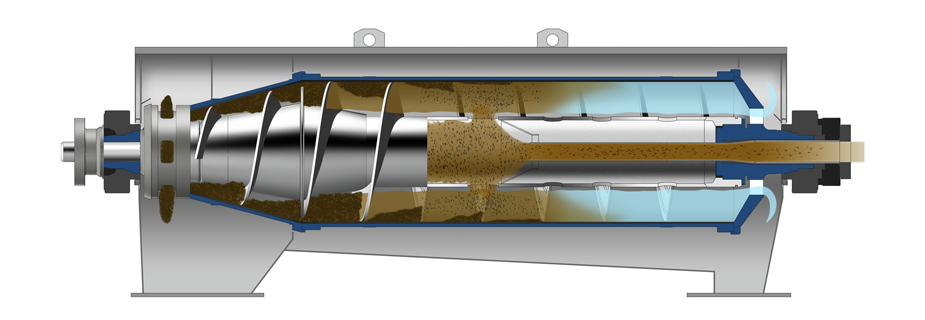

How does a Flottweg C-series Decanter work?

The concept corresponds to the fundamental function of a decanter centrifuge. The Flottweg C-series accelerates the supplied separation medium particularly effectively, thus saving energy. The solids are thrown onto the inner wall of the bowl by acceleration and discharged via the decanter scroll to the conical bowl end.

In contrast to other decanter centrifuges, the C-series decanter have a double cone and a baffle plate. The double cone reduces the distance between decanter bowl and scroll. This presses the solids against the baffle plate and increases the pressing effect. The separated water flows away without pressure along the screw.

Product features

Efficiency

Behind the designation C-series is a waste water treatment decanter centrifuge with an optimum price/performance ratio. The decanter bowl is designed to increase the volume of sedimentation in the bowl. This increases the power density. Nevertheless, the decanter centrifuge requires only little space.

The special design of the scroll ensures the highest dry solids values in the discharged material. If the DS value can be increased from 23 percent to 25 percent, Flottweg customers achieve a reduction in sludge volume of about eight percent. This also reduces transport and disposal costs by 8% - an enormous savings potential for sewage treatment plants. The powerful Simp Drive® drive supports the performance of the decanter centrifuge. It allows the bowl speed and differential speed to be controlled independently during operation. This ensures a constant dry solids value in the discharged material under varying feed conditions.

The optimized geometry of the bowl and scroll reduces the need for flocculants. This further saves operating costs.

- High dry solids values in the discharged material

- Higher power density within a small footprint

- Powerful Flottweg Simp Drive® drive

- Reduction of operating costs due to reduced need for flocculant

Power requirements

Our decanters of the C-series are considered to be genuinely economical both in terms of flocculant consumption and energy needs. The special design of the centrifuge and the Simp Drive® drive makes the waste water decanter particularly economical.

The energy consumption of the decanter can be further reduced with the installation of the Recuvane® system. The decanter must consume energy to accelerate the product to the working speed. This is when most of the energy is consumed. After separation, the liquid (centrate) leaves the system pressure-free. The energy contained in the water is lost. Customers recover part of this rotational energy through the Flottweg Recuvane® system. The special design of the Recuvane® system allows the centrate to be selectively discharged. The energy recovered during the discharge supports the main drive. Depending on the depth of the pond and the composition of the product, 10 to 30 percent of the drive energy can be saved.

- Additional energy recovery with the Flottweg Recuvane® system

- Economical bowl and scroll drive

- Reduces the energy consumption of your decanter by 10 to 30 percent.

Maintenance

The C-series is designed for easily maintenance access. Rotor and scroll can be quickly mounted and dismounted. This reduces downtime and lowers maintenance and service costs. Worn parts can be easily replaced on site. In addition, the decanter centrifuges are equipped with a comprehensive wear protection package. The inlet and outlet openings are especially protected against wear. All components in contact with the product are made of high-quality stainless steel. This additionally extends the service life of the waste water decanter and reduces the expenditure for maintenance and servicing.

- Fast assembly and disassembly of rotor and scroll reduce service and maintenance costs

- Comprehensive abrasion protection package

- All decanter components that are in contact with the product are made of high-quality stainless steel

- Easy maintenance on site due to simple replacement of wearing parts

Automation

Numerous automation options allow the decanter centrifuges to operate 24 hours a day, thus reducing personnel requirements. This in turn reduces costs incurred by the waste water treatment plant. Bowl and differential speeds can be automatically controlled via the Simp Drive®. Fluctuations in the feed can be compensated at any time in order to always achieve optimum dry solids in the dewatered material.

On request, the dosing of the flocculant can also be automated. The demand is monitored in real time. This reduces polymer consumption and saves operating costs. In addition to a low polymer consumption, all options for remote monitoring and remote service are available - for Enterprise 4.0 operation.

Our C-series decanter centrifuges are part of an overall waste water treatment process. All its components must work together optimally to ensure that the system operates efficiently and safely. Therefore, the centrifuge control of our waste water decanters can be individually integrated into the complete sewage treatment plant control system for more efficiency and operational safety.

- Minimal personnel required all the way to automatic 24-hour operation

- Fully automatic regulation of bowl and differential speed at all times for optimum dewatered dry solids

- On request, all remote monitoring options and maintenance options are available

- Automatic flocculant dosing additionally reduces polymer consumption (optional)

- Individual integration of the centrifuge control system into your overall control system for maximum efficiency and operational safety of your plant

Decanter centrifuge wins over belt press

Decanters and belt presses are in constant competition for the dewatering of sewage sludge in sewage treatment plants.

However, the experience of the West Central Conservancy District sewage treatment plant in Indianapolis speaks for itself. You can see the results in this video.

C2E

Dimensions [mm/ft]* | 2700x900x800 / 8,86x2,95x2,62 |

Weight [kg/lb]* | 1400 / 3080 |

C3E

Dimensions [mm/ft]* | 3000x1100x900 / 9,77x3,61x2,92 |

Weight [kg/lb]* | 1765 / 3883 |

C4E

Dimensions [mm/ft]* | 3500x1100x1000 / 11,55x3,74x3,35 |

Weight [kg/lb]* | 2760 / 6072 |

C5E

Dimensions [mm/ft]* | 4100x1500x1200 / 13,35x4,95x3,97 |

Weight [kg/lb]* | 5030 / 11066 |

C7E

Dimensions [mm/ft]* | 4800x1700x1400 / 15,74x5,64x4,56 |

Weight [kg/lb]* | 8200 / 18040 |

C8E

Dimensions [mm/ft]* | 5900x2000x1500 / 19,39x6,56x4,82 |

Weight [kg/lb]* | 13070 / 28754 |