- Maximize drilling efficiency with German-engineered separation excellence

- Worldwide proven expertise in drilling mud separation

- Specialized wear protection extends equipment life in drilling applications

Treatment Of Drilling Mud, Emulsions and Fluids With Decanter Centrifuges

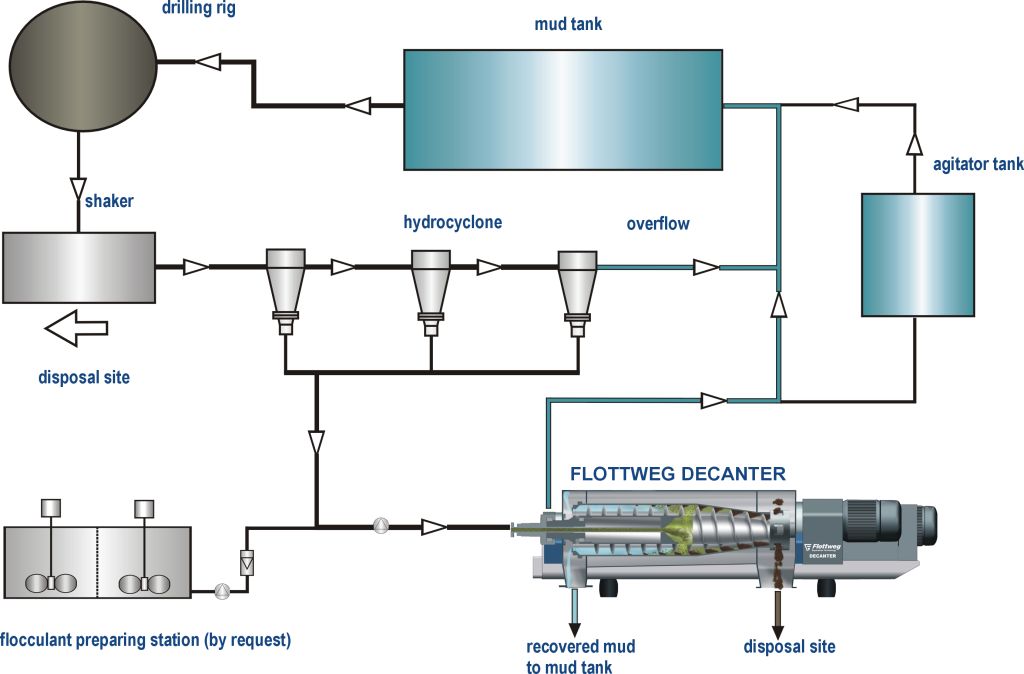

Modern drilling emulsions form a closed circuit from which no solids emerge. As a result, everything that gets into the emulsion due to the drilling process must be separated out. While riddle screens and hydrocyclones separate coarse-grained particles, the decanter deals with small particles.

The Decanter Can Be Used In Various Applications Relating To Drilling Mud

- Separation of drilling emulsions

- Processing of drilling slurry

- Processing of drilling muds

Processing of drilling emulsion, drilling slurry and drilling muds

Processing of drilling emulsion, drilling slurry and drilling muds

Your Advantages In Processing Drilling Mud and Emulsions:

- Reduction in disposal costs

- Reduction in the quantity of sludge in the closed system

- Cost saving of up to 60% for maintenance and upkeep

- Reduction in wear, especially on the slurry pump and drill bit

- Extended sludge service life

Flottweg - Your Partner For Processing Drilling Mud and Emulsions:

Worldwide, a hundred decanters are already in use in the drilling slurry industry. Flottweg has a broad range of experience and numerous references that offer you decisive advantages:

- Decanters specially adapted to the drilling slurry, with special wear protection

- "Made in Germany" - Production of the decanters exclusively in Germany, with high-quality materials and trained specialists

- Many years of experience and relevant specialist knowledge in the use of decanters for processing drilling slurry, drilling emulsions and drilling muds

- Inexpensive, worldwide aftersales service and a comparatively low amount of maintenance work

- Personal support, on-site service and project planning individually tailored to your requirements

Get advice from our experts now