Flottweg

Separator

Highest speed for finest substances

Centrifugal separators for clarifying and separating liquidsFlottweg's disc stack centrifuges epitomize German engineering excellence, offering robust purification and clarification for a diverse range of applications. These separators stand out with their impressive centrifugal accelerations of over 12,000 g, optimizing liquid processing beyond the limits of decanter centrifuges. The innovative disc stack design ensures efficient solids separation and maximized liquid phase purity, while the Soft Shot® discharge system guarantees smooth operation with accurate partial and full discharges in any combination. Flottweg's separators are not only powerful, thanks to their three-phase standard motors and belt drives, but also offer flexible speed regulation and efficient lubrication systems for long-term reliability. Safety is paramount, with all components manufactured to withstand the rigors of high-force operations, ensuring a continuously safe separation process. Tailored to meet specific customer requirements, these separators integrate seamlessly into existing systems, marking them as the final stage in a comprehensive purification process.

From algae harvesting to beer clarification and protein extraction: If you want to separate or purify liquids or remove ultra-fine particles you need strong and robust separators. With their enormous centrifugal acceleration of up to over 12,000 g, Flottweg separators are real purification and clarification all-rounders - highest quality made in Germany.

Where decanter centrifuges reach their performance limits, the use of separators begins. Thanks to their high speeds, they are able to optimally process liquids. Clarifiers (2-phase separation), separate the finest solid particles from a liquid. As purification separators (3-phase separators), they separate liquid phases of different densities and simultaneously remove solids.

The Flottweg separators do not lose their composure even at acceleration forces of more than 12,000 g. Their compact, robust design ensures smooth running and simplifies maintenance. The disc stack and the distributor ensure optimum flow conditions in the bowl. They thus enable highly efficient solids separation and maximum separation efficiency in the separation of liquid phases. The number of wear parts and seals is reduced to a minimum, reducing downtime and operating costs..

In addition, Flottweg's know-how as a system partner is also important, because the separator is usually the final processing stage in a larger purification process. It is often combined with an upstream decanter or Tricanter®. Flottweg designs the process individually according to customer requirements and also finds the best possible separator solution that combines with existing piping and plant systems.

The Flottweg disc stack centrifuges are available in two basic versions

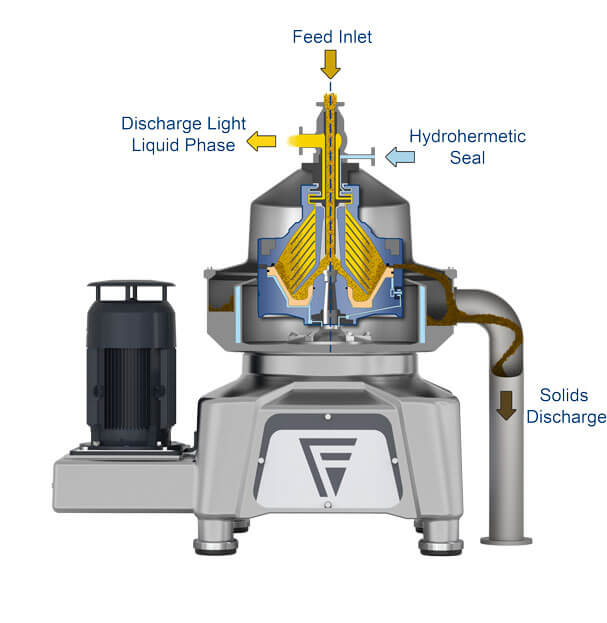

How the Flottweg Separator works (example clarifier)

The product to be clarified runs through an inlet pipe into the interior of the separator bowl. Then the distributor gently accelerates it to full speed. The disc stack in the bowl divides the product stream into many thin layers, thus creating a large surface area. Within the disc stack, the centrifugal force causes the solids to separate from the liquid and settle at the edge of the bowl.

The separated material particles are periodically removed via a hydraulic system in the lower part of the bowl at maximum speed. The clarified liquid flows from the disc stack to a centripetal pump and is discharged under pressure.

If a purification separator is used instead, the liquid mixture within the disc stack separates into its light and heavy liquid phase. The solids are discharged simultaneously.

Product features of a disc stack centrifuge

Power

The high acceleration of separators is dependent on a powerful drive with a long lifetime. Flottweg supplies a standard three-phase AC motor to provides the necessary power. It transmits the power to the bowl spindle by means of a belt and runs very quietly. The speed can be easily and flexibly adapted to the respective product conditions via a frequency converter. The separator quickly reaches full operating speed and just as quickly accelerates to the speed limit again after discharging solids. At the same time, the inverter reduces both the power consumption and the mechanical load on the system. A completely closed lubrication circuit system protects the spindle bearings. The machine is also always fully lubricated when starting up and stopping, which guarantees a long service life of the bowl bearings. A pump unit ensures exact and demand-oriented metering of the lubricating oil.

- powerful three-phase motor with belt drive

- rapid acceleration with extremely quiet running

- flexible speed regulation via frequency converter

- completely closed, efficient lubrication circuit system

Safety and security

With the particularly high forces that separators generate, safety is a central issue. With the Flottweg Separator, users have a reliable technology for a continuously safe separation process. This is based on the high-quality, wear-resistant components that Flottweg develops and manufactures 100 percent in Germany. All safety-relevant parameters can be monitored via a programmable logic controller. A high level of operational dependability of the drive is ensured by an automatically monitored lubricant supply. The Soft Shot® emptying system is an outstanding feature for the protection of the operator. It can lower the sound pressure level at partial and full discharges to such an extent that the separator does not require any special sound insulation measures. In the event that there is a risk of explosion during the processing of materials, the option of inerting can be used. It prevents the escape of vapors into the atmosphere (contamination) or the entry of air into the equipment (oxidation).

- high component quality "Made in Germany"

- automatically monitored lubricant supply

- noise attenuation through Soft Shot® emptying system

- optional: Inerting as protection against contamination and oxidation

Hygiene

Whether food, pharmaceutical products or chemicals: The Flottweg separators are fully equipped for the hygienic requirements in highly regulated industries. They meet all requirements of the valid centrifuge standard and are designed according to the principles of "Hygienic Design". In the food and pharmaceutical industries, all components in contact with the product are CIP-capable (Cleaning in Place). These AC (Automatic Cleaning) separators can also be easily integrated into existing production and CIP processes. For certain industrial applications, Flottweg equips its separators with super duplex stainless steels to achieve, for example, a greater higher resistance to chlorides.

- construction according to the principles of Hygienic Design

- automatic CIP cleaning (Cleaning in Place)

- super duplex stainless steels for industrial applications

Operation

Efficient operation in clarification or separation processes also requires simple operation and easy maintenance. Thanks to their compact design, Flottweg separators are particularly easy to maintain. For example, the separator bowl is easy to assemble and disassemble. Components such as the belt drive are designed to be wear resistant, which extends the maintenance intervals. The heart of the process control system is a programmable logic controller (PLC). It automatically monitors and controls the separator and all its components: Motor protection and start-up regulation with frequency converter, time control for the automatic emptying of the bowl, valves and auxiliary equipment. The operator always has an overview of the process via the associated displays and alarm lamps.

- easy to maintain due to compact design

- less maintenance thanks to low-wear components

- simple programmable logic controller (SPS control)

„Amazingly easier“

The US brewery Alltech's Lexington Brewing & Distilling Co. produces award-winning beers and spirits, including its flagship Kentucky Bourbon Barrel Ale®. In order to make the brewing process more efficient and simpler, the producer made the decision to use the Flottweg Separator. You can find out why and with which results in this video.

More about Flottweg separator

Extras for maximum efficiency and safety:

Are you interested in Flottweg separators?

Would you like to know more?

Get in touch with us or write to us!