- Recover 90% of process water while reducing environmental risks from tailings storage

- German-engineered centrifuges require 75% less space than traditional dewatering systems

- 24/7 continuous operation with consistent performance

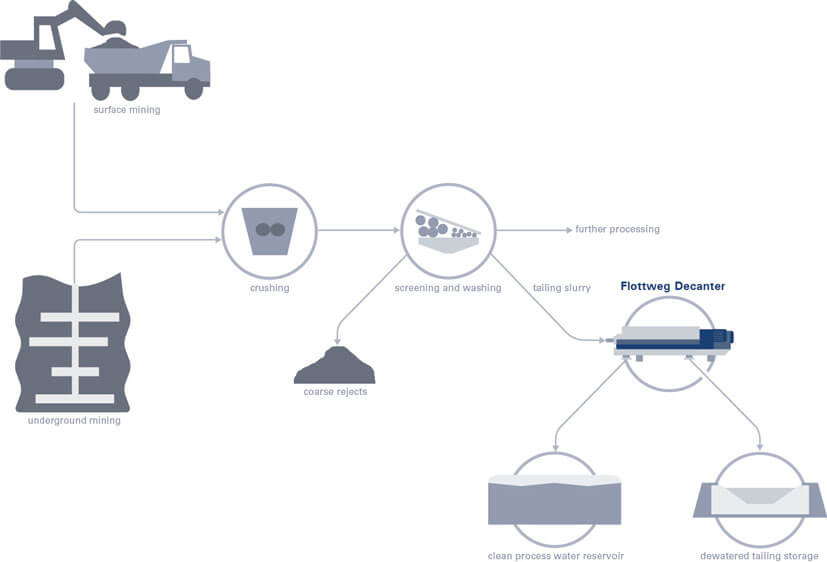

Save water and cost by dewatering tailings

Tailings are still frequently stored in large settling basins or sludge ponds. They are a great burden on the environment. The process water bound by the tailings remains unused. With modern dewatering solutions, mining residues can be treated economically and the process water that they contain can be recovered. This saves both space and cost and is environmentally friendly.

In mining, the term tailings refers to fine-grained residues in the form of sludges. They are created during the processing of ores and minerals. The resulting waste water or overburden sludge is partly contaminated with chemicals. Tailings are a risk to the environment when stored in sludge ponds. If the dam breaks, this can have a significant impact on humans and the environment.

The storage of tailings in sludge ponds is increasingly being replaced by the storage of dewatered tailings. Mining companies store the dewatered sludge on the ground. This complies with statutory regulations in most countries. In hard-to-reach and confined storage regions or in earthquake-prone areas, it is particularly advantageous if the tailings have been dewatered. This minimizes environmental risks and space requirements. The cleaned process water can be recycled. Mine operation costs are significantly reduced.

Our decanter centrifuge for processing tailings

Customer advantages

Recycling of captured process water

Flottweg decanter centrifuges use considerably less fresh water than belt presses or chamber filter presses. Our decanter centrifuges efficiently separate solid particles down to a size of 10 µm without using flocculants. If the operator uses flocculants, it is possible to separate even finer solids from the liquid (water). The recovered process water is then clean enough to be returned to the process. As a result, mine operators can significantly reduce fresh water requirements.

Filter presses, such as belt presses and chamber filter presses, rely on the use of filter cloths or filter belts to process the overburden sludge. During prolonged use, deposits accumulate in the filter cloths and filter belts. This reduces the degree of dewatering.

Decanter centrifuges operate continuously - often around the clock. They do not require filter cloths and filter belts. A constant dewatering rate is therefore assured.

- Recycling of the cleaned process water

- Constant dewatering capacity

- Operation around the clock is possible

- Demand for fresh water is significantly reduced

Installation in confined areas

Mines or mining operations are often located in confined and difficult to reach locations. The space taken up by the dewatering system is an important factor. Given the same capacity and throughput, decanter centrifuges require considerably less space than other processing plants. Flottweg decanter centrifuges can be installed almost anywhere - either as a fixed installation in a building or as a semi-mobile container unit. Our centrifuges only need a ground area of 5 x 10 meters.

A comparison

With a hydraulic capacity of 100 m³/h and a solids load of 25,000 kg, there are considerable differences in the weight of the plant:

Chamber filter press: 120 tons

Belt press: 65 tons

Flottweg centrifuge: 16 tons

Increased safety in tailings storage

Dewatering tailings makes it possible to store dry processed sludge. Dry storage means a lower risk. The amount of wastewater in the settling ponds and the pressure on the dams is reduced. This significantly reduces environmental risks.

Flottweg decanter centrifuges for dewatering tailings are manufactured only in Germany. Thus we can ensure the optimal quality of our machines. The quality of the materials used in mining and quarrying plays an important role. Materials which come into contact with the sludge are attacked by the sludge's abrasive components. A high-quality wear protection is therefore a must.

Special materials, coatings and supplementary measures ensure that the service life of Flottweg decanter centrifuges spans many years. Flottweg centrifuges allow for the easy replacement of wear parts such as inlet bushings. This saves time and reduces the cost of maintenance and servicing throughout the entire life of the machine.

If maintenance is due, our worldwide service team is always at your disposal.

- Minimization of environmental risks (such as dam breaches)

- Made in Germany, for a long service life

- Significantly reduced maintenance cost

- Worldwide service network available at any time

Flottweg decanter centrifuges are a real alternative to traditional processes

Decanter centrifuges are increasingly finding their way into modern mining processes due to their low cost, low fresh water usage and low space requirements as well as their contribution to environmental protection.

The Tiebaghi Nickel Mine in New Caledonia was able to recover 90% of its process water by using Flottweg centrifuges. Learn more about the results in the following article:

Dewatering tailings with Flottweg decanter centrifuges