Flottweg

Tricanter®

Three phases with the highest selectivity

The efficient 3-phase decanter centrifugeExperience the power of Flottweg’s Tricanter®. Our technology ensures optimum separation results, continuous separation, and high selectivity in oily sludges treatment, starch production, and fat recovery. With cost savings, versatility, and adaptability to changing conditions, our Tricanter® offers the highest quality, made in Germany, for long-term benefit. Discover how Flottweg is optimizing the industry. Get in touch today to learn more!

In the classic separation process, solids are separated from a liquid, or two liquids of different densities are separated. But often both come together. This is exactly where the Tricanter® from Flottweg is the right solution. It allows the continuous separation of three phases (solid-liquid-liquid) in a single process. This is attractive, for example, in the treatment of oily sludges, in starch production and in fat recovery.

More than 40 years ago, Flottweg developed the Tricanter® to separate three phases in a single simultaneous process. The prerequisites for this are that the liquids are not soluble in each other, that they have different densities and that the solids phase has the highest specific weight. On this basis, the specially designed impeller system produces optimum separation results.

Three-phase separation offers users several advantages: The combination of the processing steps eliminates the need for additional separation stages, which results in considerable cost savings. In addition to its high selectivity, the Tricanter® is particularly attractive because of its versatility. It can adapt to changing inlet conditions at any time. In addition, there are the proven engineering and Flottweg services, from application-oriented project planning, through commissioning, to maintenance and spare parts supply. Thus, users benefit in the long term from the highest quality "Made in Germany."

Get guidance nowThe application range of the 3-phase centrifuge

How the Flottweg Tricanter® works

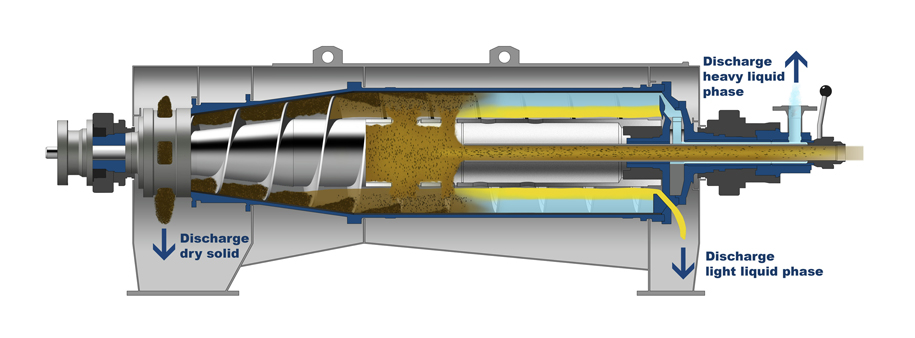

The design and function of the Flottweg 3-phase centrifuge is similar to that of a decanter (two-phase separation). Solids settle on the inner wall of the bowl when subjected to centrifugal force. The scroll constitutes the conveying tool. Under centrifugal force, solids settle on the inner wall of the bowl.

The decisive difference to the decanter lies in the separate expulsion of the two liquid phases: With the Tricanter®, the heavy liquid is discharged under pressure via an adjustable impeller. The light liquid flows off without pressure. The impeller allows infinite adjustment of the pond depth during operation and thus fast, precise adaptation to changing feed conditions - without interrupting operation.

Three-phase separation with the Tricanter® Flottweg

Three-phase separation with the Tricanter® Flottweg

Product features

Efficiency

The Tricanter® guarantees a high level of economic efficiency, because the continuous three-phase separation eliminates the need for further processing steps and separation stages. The particular strength of the Flottweg Tricanter® is demonstrated by the highest possible purity of the liquid phases to be separated through the use of the impeller. The separation process can be adapted at any time to changing conditions (product in the inlet). Individually manufactured decanter scrolls ensure the best separation results. In addition, Flottweg decanter bowls have application-optimized geometries. Tricanter® is manufactured exclusively in Germany to the highest quality standards.

- economical three-phase separation

- highest possible purity of the phases to be separated due to the adjustable impeller

- flexible adaption to changing inlet conditions

- individually manufactured decanter scrolls

- decanter bowls with application-optimized geometries

Safety and security

The safety of the Tricanter® is a central theme because of its high speeds, its continuous operation and its diverse fields of application. Flottweg offers maximum process reliability thanks to application-oriented wear protection, medium-based material selection, machine configuration and worldwide service. High machine safety is also guaranteed, as machines are designed according to current guidelines and monitored by various sensors and evaluation systems (e.g. vibration). In the case of flammable mixtures, explosion protection in accordance with the ATEX directive and current standards is also provided.

- application-related wear protection

- medium-based material selection and machine configuration

- worldwide service

- monitoring by sensors and evaluation systems

- explosion protection according to ATEX directive

Hygiene

Hygiene requirements are very high, especially in food processing - a central field of application for the Tricanter®. Flottweg designs and manufactures its centrifuges consistently in accordance with "Hygienic Design." In the food industry, all components in contact with the product are CIP capable (Cleaning in Place) and therefore designed for automated washing.

- construction according to the principles of Hygienic Design

- CIP cleaning (Cleaning in Place)

Operation

Flottweg Tricanter® are particularly easy to operate and maintain due to their application-optimized and compact design. An automated process is possible with impeller adjustment via an actuator. In addition, the intuitive InGo user interface makes control very easy. InGo simplifies and accelerates the sometimes highly complex processes involved in centrifugation. The operating concept is available for all Flottweg Tricanter®.

- easy to maintain due to compact design

- Adjustable impeller

- optimized control through InGo operating concept

360° view of the Flottweg Tricanter®

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

From manual to fully automatic oil / air lubrication, we can meet all customer requirements.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

From manual to fully automatic oil / air lubrication, we can meet all customer requirements.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Depending on requirements, the materials are also suitable for use in the food industry.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Depending on requirements, the materials are also suitable for use in the food industry.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Depending on requirements, the materials are also suitable for use in the food industry.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Depending on requirements, the materials are also suitable for use in the food industry.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Depending on requirements, the materials are also suitable for use in the food industry.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Depending on requirements, the materials are also suitable for use in the food industry.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

Depending on requirements, the materials are also suitable for use in the food industry.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Depending on requirements, the materials are also suitable for use in the food industry.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Depending on requirements, the materials are also suitable for use in the food industry.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

Depending on requirements, the materials are also suitable for use in the food industry.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

Depending on requirements, the materials are also suitable for use in the food industry.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

For easy assembly and disassembly, our belt guard can be disassembled into individual segments and opened.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

From manual to fully automatic oil / air lubrication, we can meet all customer requirements.

The adjustable impeller can be controlled fully automatically and facilitates optimal separation.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

From manual to fully automatic oil / air lubrication, we can meet all customer requirements.

Our Flottweg wear protection includes several measures. For example, depending on the application, our solids discharge can be additionally reinforced.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

From manual to fully automatic oil / air lubrication, we can meet all customer requirements.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

From manual to fully automatic oil / air lubrication, we can meet all customer requirements.

An additional housing rinse allows the housing to be easily cleaned and integrated into CIP processes in hygienic applications.

The housing covers of our small and medium-sized Tricanter® can be easily opened at the customer’s request. Access to the rotor and drum is therefore easy.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

From manual to fully automatic oil / air lubrication, we can meet all customer requirements.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

Flottweg proprietary Simp Drive® drives the bowl and scroll independently of one another, ensuring optimal separation results.

The heart of the Tricanter® is located under the housing: Rotor and scroll.

From manual to fully automatic oil / air lubrication, we can meet all customer requirements.

The Flottweg 3-phase decanter centrifuge - two machines in one

Süpro GmbH from Lampertheim-Hüttenfeld in southern Hessen recycles around 40,000 tons of animal by-products annually. For the processing of fats, the company initially used a decanter and a downstream separator.

Then they decided to switch to a single Tricanter®, with success, as the video shows.

More about Flottweg Tricanter®

Flottweg Tricanter® of the Z-series

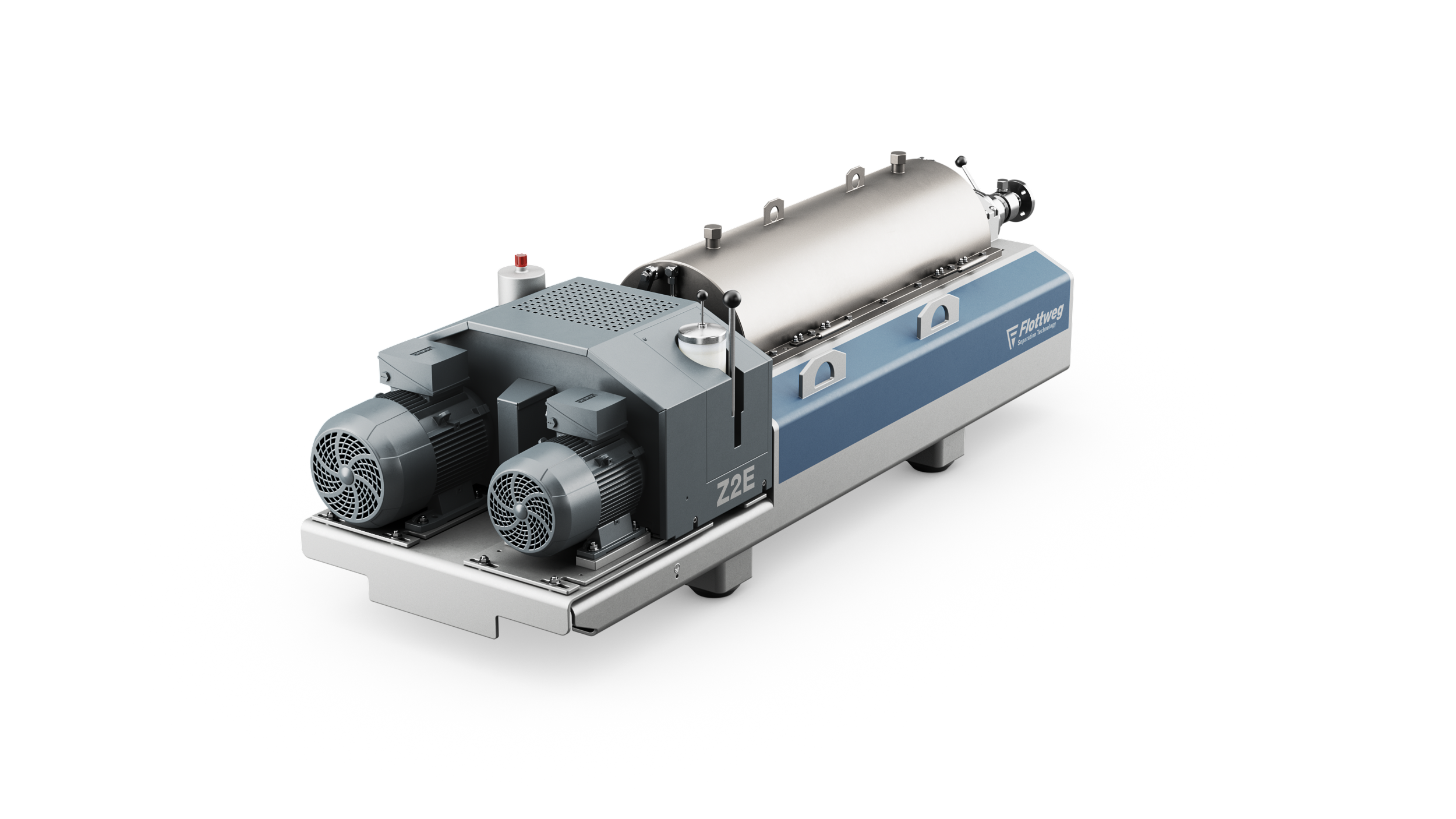

Z2E

Dimensions [mm/ft] | 2500x700x700 / 8,2x2,39x2,33 |

Weight [kg/lb] | 1250 / 2849 |

Z3E

Dimensions [mm/ft] | 3100x800x800 / 10,3x2,76x2,72 |

Weight [kg/lb] | 1600 /3520 |

Z4E

Dimensions [mm/ft] | 3800x1000x1200 / 12,53x3,28x3,94 |

Weight [kg/lb] | 3000 /6600 |

Z5E

Dimensions [mm/ft] | 4500x1600x1100 / 14,86x5,12x3,71 |

Weight [kg/lb] | 6200 / 13640 |

Z6E

Dimensions [mm/ft] | 5200x1.800x1300 / 17,09x5,81x4,13 |

Weight [kg/lb] | 9750 / 21450 |

Z8E

Dimensions [mm/ft] | 6400x2000x1500 / 21,12x6,56x4,85 |

Weight [kg/lb] | 14140 / 31108 |

Features for process optimization

Are you interested in Flottweg Tricanter®?

Would you like to know more?

Get in touch with us or write to us!