- Maximum recovery of valuable materials from whey with Flottweg separation technology

- Hygienic design according to FDA standards for highest product quality

- Maximized yield through customized whey processing solutions

Efficient whey processing

Flottweg separation technology and separation solutions for industrial whey treatment

In the production of cheese, the largest proportion of the milk that is processed ultimately becomes whey. However, this whey is more than just a by-product: It contains valuable ingredients such as lactose, whey protein and minerals. The modern dairy industry converts the resulting whey into valuable products - ranging from whey drinks and baby food to additives for pharmaceuticals. Before further processing of the whey, any remaining residues, such as cheese curd particles (cheese dust) and residual milk fat, can be separated from the pure whey and recovered. Both components are valuable raw materials for dairy products. By using industrial centrifuges to remove dust and to skim milk fat, the yield and the recovery of valuable by-products can be maximized.

Our machines for the industrial processing of whey:

How is whey treatment performed?

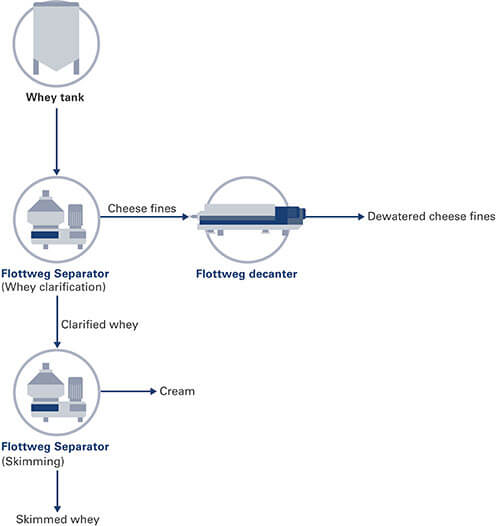

1. Removal of dust from whey

For cost-effective processing and to increase yield, residual dust is removed from the whey upstream using an industrial 2-phase separator. Once the dust has been removed from the whey, the whey can be skimmed in the next processing step.

2. Dewatering of cheese dust

The concentrate of fine curd components obtained from the decanter is further dehumidified using the Flottweg decanter until a free-flowing cheese mass is produced. The dry solids content can be flexibly adjusted according to the type of whey and the desired consistency. Consistent hygienic processing also makes it suitable for use in the food sector, for example in melted cheese products.

3. Whey skimming

During cheese production, some of the milk fat remains in the whey. The separated fines can be used, e.g., in the production of butter. As milk fat is a high-quality component of whey, the cost-effective recovery leads to a rapid amortization of the investment. The whey can then be further processed and used for the manufacture of a wide variety of products such as lactose, whey drinks, etc.

Highest hygiene standards for whey processing

Hygiene standards play a decisive role in whey processing and serve to safeguard the highest product quality. Flottweg separators and decanters are specially designed for food applications and meet the highest quality standards. They are fully CIP-capable and permit efficient cleaning. The seals and lubricants used are made of FDA-compliant food-grade material that prevents contamination. In addition, all parts that come into contact with the product are made of high-quality stainless steel and thus meet the highest hygiene standards and requirements.

Your advantages when dewatering whey:

Maximum efficiency through upcycling

The process of converting a by-product back into a valuable material makes it possible to operate sustainably and economically at the same time. Once the dust and milk fat have been removed from the whey, the bi-products (cheese dust and milk fat) can be further utilized. Recovery reduces waste in production and increases yield and profit.

Corrosion-resistant materials

Many process streams in dairies have an increased chloride content. Flottweg centrifuges are manufactured from specially selected materials for maximum corrosion resistance. As a result, you will benefit from a centrifuge with a long service life.

Customized solutions

We support our customers with detailed analysis and advice. In addition to laboratory tests, we offer pilot tests using test machines to determine the exact configuration of whey processing machines. As a second step, we also consider the ideal integration into your dairy - from the peripherals to various automation solutions.

Optimized user-friendliness

The Flottweg whey centrifuges are characterized by their intelligent design, which facilitates user-friendly operation utilizing the touch panel. The robust and maintenance-friendly system guarantees maximum machine availability.