- Up to 70% less water consumption - sustainable and resource-saving

- Maximum starch yield and top quality thanks to innovative separation technology

- Up to 30% less dry matter - significantly lower transport and drying costs

Efficiency in tapioca starch extraction across all process stages

Separation solutions for the production of tapioca starch from the manioc root.The process of extracting tapioca starch from the manioc root, otherwise known as the cassava root, is complex and cost-intensive. Industrial centrifuges from Flottweg help foster a more economical production process and contribute to high product quality.

Compensation for natural variances in raw materials

Flottweg decanters efficiently separate the amniotic fluid from the tapioca gratings. This removes protein fractions and other soluble substances, resulting in improved starch quality, increased starch yield and optimized water usage in subsequent process steps.

Lower water consumption

The gratings decanter reduces water consumption in downstream process steps. Early amniotic fluid separation removes a major portion of the proteins that form a slimy deposit on downstream processing equipment. This saves enormous amounts of washing water, which would otherwise be used to remove the deposit.

High-quality, high-purity starch

After extraction, the Flottweg nozzle separator refines and concentrates the starch as efficiently as possible in order to achieve optimum quality.

Pay less for more

Once the starch has been extracted, producers dewater the resulting tapioca pulp (or fiber) to reduce transport and drying costs.

Our separation solutions for tapioca extraction

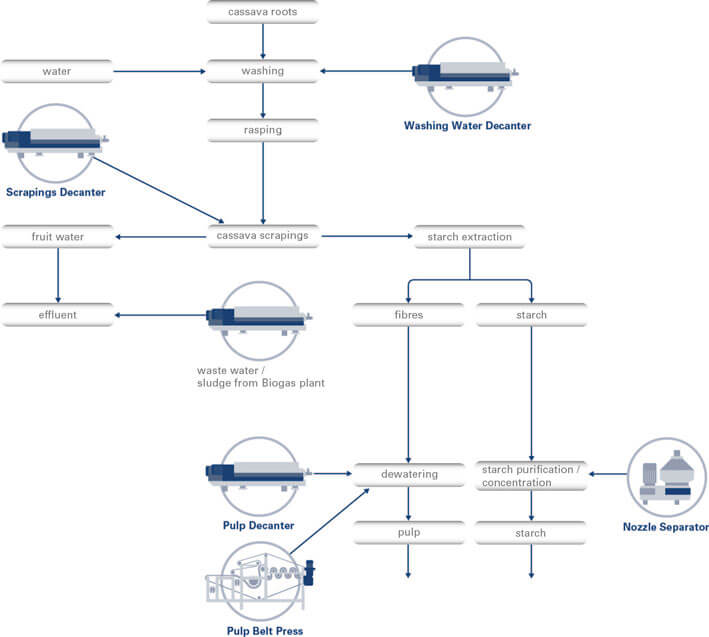

Tapioca Starch Extraction Process

To start, the manioc roots are cleaned in wash drums to remove any soil and dirt deposits; they are then coarsely chopped and crushed. The wash water is clarified in ponds for reuse later in the process. The remaining sludge is dewatered using Flottweg decanters.

After crushing, the root pieces are ground into a so-called grated pulp with the help of special machines and then diluted with water. Here, the goal is to break down the cells and release the starch grains. A grating decanter separates a large part of the fruit water (centrate) from the starch-fiber fraction (solid phase). Approx. 70% of the soluble substances are thus separated from the amniotic fluid. This reduces downstream water consumption, improves tapioca quality and increases the yield of tapioca starch.

The discharged solids phase consists largely of starch, fibers, salts, sand and minerals. During an exctraction process, the starch is purified and concentrated. Centrifugal sieves separate the fibers from the starch milk. The nozzle separator then washes and concentrates the starch, removing impurities. Depending on the customer’s process, two- or three-phase versions of the nozzle separator are used. In a final process step, the purified starch is mechanically pre-dewatered and dried. Flottweg decanter centrifuges dewater the separated fibers, also known as pulp, to reduce transport and drying costs.

Customer benefits

Efficient use of resources

Industrial centrifuges are used to separate the tapioca gratings from the amniotic fluid. The mixture of gratings and fluid contains a high quantity of solids. Therefore, a powerful drive like the Flottweg Simp Drive® is indispensable in this application. The industrial centrifuge separates high amounts of tapioca gratings in a short period of time. Efficient separation of the amniotic fluid increases the service life of the system, conserves resources (like water), produces better quality starch, and increases the starch yield.

Flottweg decanter centrifuges are equipped with the Recuvane® system for maximum energy efficiency. Targeted drainage of the separated liquid saves drive energy and reduces energy consumption.

- Continuous separation of amniotic fluid from the starch/fiber fraction

- Reduced fresh water consumption

- Better starch quality

- Higher yield of starch

- Easier processing of old roots

- Reduced energy consumption thanks to Flottweg Recuvane®

- Positive impact on downstream process stages (e.g. centrifugal sieves)

More starch with better quality.

To achieve high starch quality, it is essential to constantly and efficiently remove impurities from the starch. After starch extraction, the Flottweg nozzle separator refines and concentrates the starch milk. Our FDS series nozzle separators have the largest possible clarification area and can continuously process and discharge large quantities of solids. Producers consistently obtain pure and concentrated starch at the lower outlet. The nozzle separator can also be equipped with an optional washing system. This device allows process/wash water or already concentrated product to be added directly to the solids chambers upstream of the nozzle outlet. This improves the separation result and compensates for product variations in a process-safe manner.

- High purity of tapioca starch thanks to efficient displacement washing

- Constant concentration of starch milk

- High starch yield

- Consistent starch quality even under fluctuating process conditions

- Nozzle separators are available in 2-phase or 3-phase design, depending on the customer's process

Reduced drying costs

After extracting the starch, operators dewater the resulting tapioca pulp in order to reduce the transport and drying costs. Compared to screw presses, industrial centrifuges dewater with less space, and they are clean and efficient. The drier the dewatered pulp, the less material that needs to be disposed of, and the lower the cost of transportation, disposal or drying.

- Continuous dewatering of tapioca fibers/pulp

- Closed system increases operator safety, as less amniotic fluid can accumulate on the bottom

- Dewatering to up to 20–30% w/w DS content

- Reduced thermal drying costs due to a high level of mechanical dewatering

Quality Made in Germany

For durability and reliability, our machines are developed and manufactured exclusively in Germany. Our industrial centrifuges include numerous features that further enhance performance. Our decanter centrifuges are equipped with the powerful Flottweg Simp Drive® drive. The drive ensures high differential speeds and automatically adapts to changing conditions during operation. This provides consistent separation results even with product variances.

For the longest possible service life and minimum downtime, our decanters have special wear protection — adapted to the conditions encountered in starch production.

Whether in Thailand, Vietnam or the Philippines, Flottweg has decades of experience and numerous references related to the production of tapioca starch. We know what matters to producers.

- Quality Made in Germany

- Powerful Simp Drive® drive

- Special wear protection for long service life

- Numerous references in Southeast Asia.

Natural all-rounder starch – interview with sales engineer Manfred Kropp

Starch is a product that repeatedly plays an important role in many areas of everyday life. But how can starch be obtained and what are the key challenges in the manufacturing process? Manfred Kropp, sales engineer at Flottweg, answers these and other questions in an interview.