- Maximum sludge dewatering for significantly reduced disposal and transportation costs

- 24/7 automated operation for non-stop water treatment

- Maximize efficiency with compact design and high dry matter results

Cost-efficient dewatering of sludge from waterworks

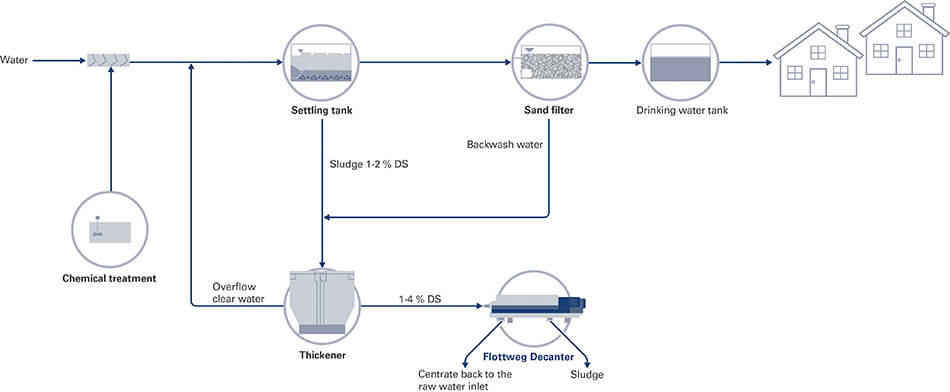

Sludge is produced when extracting drinking water from untreated water. Disposing of this sediment sludge poses a challenge for the waterworks. Transport and landfill costs can be significant, increasing the overall cost of water processing.

This is where Flottweg separation technology comes into play. This offers an optimized solution for dewatering and volume reduction of waterworks sludge. By using state-of-the-art technologies and separation processes, Flottweg can effectively dewater the waterworks sludge and thus reduce its volume. This reduces the disposal costs associated with the recovery of drinking water.

Our machines for the dewatering of waterworks sludge

Your benefits when dewatering and processing waterworks sludge with Flottweg centrifuges

Optimized user-friendliness

Flottweg centrifugals are characterized by their intelligent design, which facilitates user-friendly operation via the touch panel. The robust and maintenance-friendly construction guarantees maximum machine availability.

Increased efficiency

Today, efficiency and cost reduction play a crucial role in systems of all sizes. Waterworks sludge that has been dewatered with a Flottweg decanter has a high dry matter content. This leads to considerable savings in transport and disposal costs.

Low space requirement

Space requirements often play an important role. Flottweg offers compact machines that allow efficient use of space with seamless integration into existing plant infrastructure.

Continuous and automatic operation

Is it necessary to operate 24/7 without supervision? Flottweg centrifugals run independently and thus help to increase productivity by minimizing downtimes - for a continuous and uninterrupted process.