- Maximize wine yield and quality through precision German separation technology

- Automated 24/7 operation with minimal supervision and rapid cleaning cycles

- Reduce oxidation with closed-system processing technology

Optimized wine production and lees processing with Flottweg centrifuges

Higher yields, consistent quality, and maximum clarityGlobal competition, altered consumer demands, and environmental conditions are presenting the wine industry with new challenges. This makes it all the more important to rely on innovative and flexible solutions. Modern processes in must treatment and wine production are therefore essential to guarantee the best possible quality. Flexible, reliable, and easy-to-operate plant technology such as decanter centrifuges and clarifiers play a key role here. They make the efficient and gentle separation of solids and fluids possible and thus help enable a high yield and a top-quality end product.

Our machines for the industrial production of wine:

Mash pre-clarification and lees/tank bottom sediment processing

with Flottweg decanterThe lees content of the grape must is dependent on the pre-treatment of the grapes. Both harvesting technology and the way grapes are transported can have an impact on the final composition of the must. The press system used also has a major impact on the production of lees.

The machine, which is specially designed for efficient must or wine clarification, separates the turbid substances within a few seconds; the contact time is significantly reduced. In general, if the contact times are too long (e.g. static sedimentation), sediments can have a negative impact on must quality. The clarified must is gently pumped out of the machine by an adjustable impeller, and the precious liquid is discharged under pressure. The exposure of must to oxygen and thus oxidation processes are minimized. The must discharge usually only has a solids content of < 1% vol.

Fine clarification

with Flottweg separatorClarification processes do not only play a major role in must processing. Effective clarification throughout the wine production process can have a significant impact on the purity of the wine's flavor and increase its market value. It is not always possible for a winery to separate fines using a decanter centrifuge when the particles have a similar density to the surrounding liquid. This is exactly when the so-called separators are used. By design, these liquid-optimized machines operate with a higher centrifugal acceleration. Even the finest substances are separated so that must and (new) wine are efficiently clarified.

Separator-based pre-clarification helps remove the finest lees, which could adversely affect the taste of the wine during further production stages. Moreover, further fermentation is more consistent and can be better controlled.

Wines from finely separated musts can be stabilized better and are more cost-efficient. The service life of the filter is extended, which leads to savings on filter auxiliaries. By separating the lees at the must stage, the SO2 dosages required in further processing are generally reduced.

From the grape to wine

How white and red wines are produced using Flottweg separation technology

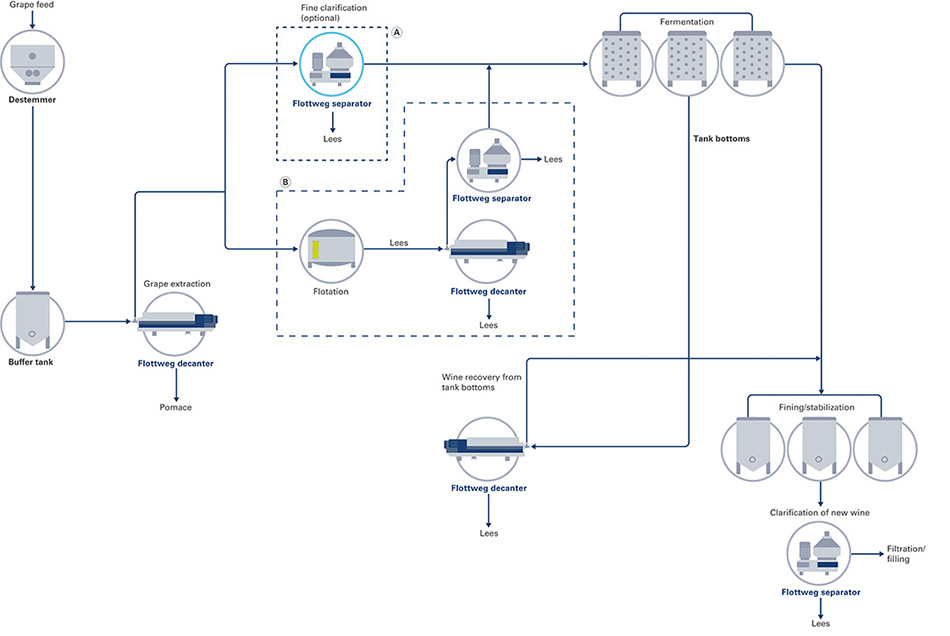

Producing white wine

The process begins with the harvesting of the grapes, followed by their further processing in a de-stemmer. This separates the stems from the pure grapes. The grapes are then temporarily stored in a buffer tank and enzymes are added if necessary. This step is crucial to maximize juice yield and increase the efficiency of the subsequent juice extraction process.

The grape juice is extracted using a Flottweg decanter, which optimizes the grape juice yield. In the subsequent process step, the must can be floated. A cap of grape marc forms, which can be processed with a decanter. During the fermentation of the wine, lees are formed that can be processed using a decanter and valuable wine can be recovered. After the fermentation, the wine is stabilized with great care to eliminate undesirable substances and to increase its shelf life. Here again, a Flottweg separator is used to separate the last solid particles and prepare the new wine for the final processing steps (filtration/bottling).

Just a single decanter or separator is sufficient for the various process steps, as the system can be flexibly customized to meet the requirements of different raw materials, product properties, and process requirements.

A typical process for the production of white wine

A typical process for the production of white wine

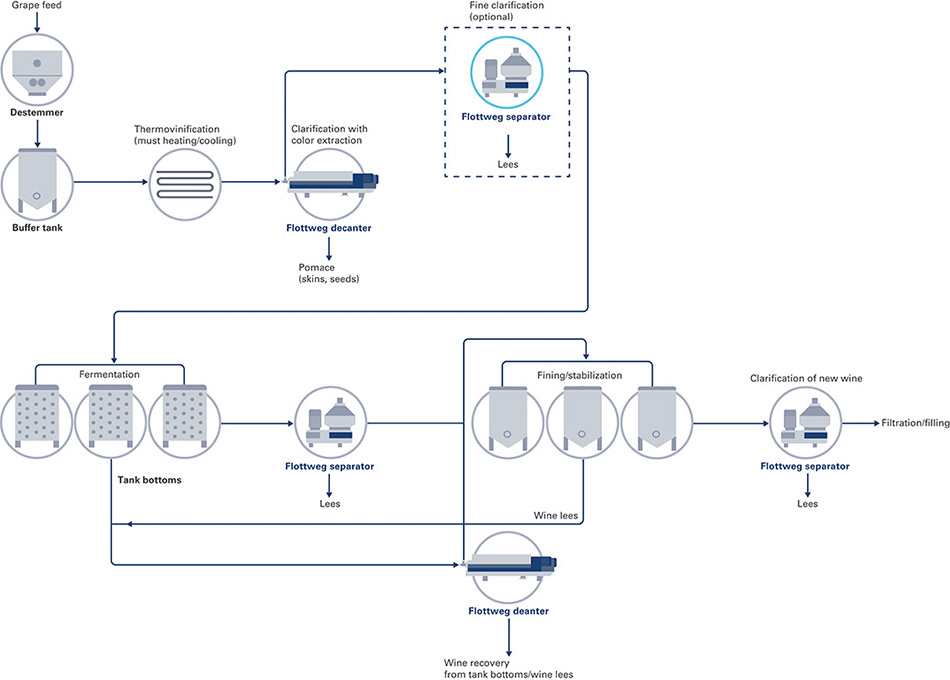

Producing red wine

Similar to white wine, the process of producing red wine begins with harvesting the grapes and then processing them in a de-stemmer. After storage in the buffer tank, thermal vinification takes place, where the grapes are heated to a certain temperature in order to extract the pigments from the skins and to promote the development of aromas. This method improves the intensity and complexity of the wine.

The subsequent grape juice extraction and clarification with extraction of the pigment is carried out using a Flottweg decanter, which guarantees an optimal product yield. Optionally, fine clarification can then be carried out using a separator to further improve the purity of the juice.

The fermentation of the wine is a critical step in which the grape sugars are converted into alcohol. During this phase, sediment forms that can be recovered with a decanter, thereby minimizing the loss of wine. The wine is clarified using a Flottweg separator before fining and stabilization in order to remove unwanted substances and increase shelf life.

Another important step is the clarification of young wine with a Flottweg separator to separate the last solids and prepare the wine for the final processing steps, such as filtration and bottling.

A typical process for the production of red wine

A typical process for the production of red wine

Your advantages when producing wine using Flottweg separation technology:

Highest throughput

Economic efficiency and cost reduction now play a decisive role in the management of companies of all sizes. The utilization of Flottweg separation technology in the production of wine offers a number of benefits. Firstly, the closed system ensures optimal quality, with a reduction in oxidation. Secondly, the technology offers the highest cost-effectiveness. The use of filtration aids is also reduced to a minimum, which simultaneously reduces disposal costs.

Greater product yield

The use of Flottweg centrifuges in the production of wine allows flexible adaptation to different grape varieties and processing methods. This increases and optimizes product yield.

Continuous and automatic operation

Is it necessary to operate 24/7 without supervision? Flottweg centrifuges run autonomously and thus help to increase productivity.

At the same time, the centrifuges have impressively short setup and cleaning times.

Intelligent machine design

Flottweg machines are not only characterized by an intelligent design, but also by the InGo user interface. This simplifies the induction training for new employees using the machine, while also providing immediate access, at any time, to the machine data required for your production process.