- Recovery of beer and wort from by-products to increase yield and profitability

- Use of modern separation technologies for high efficiency and hygienic processing

- Sustainable use of by-products to conserve resources and reduce costs

Sustainable and efficient practices for beer recovery and processing

In addition to the main product, beer, the production process also includes various by-products such as spent grain, hot trub, excess yeast, and hop sediment from cold hopping. The use of modern technologies for processing and recovery of these by-products can achieve efficient resource utilization and increase the cost-effectiveness of the brewing process.

Beer recovery aims to recover beer from surplus yeast, excess yeast, or cold hopping after fermentation or maturation. This allows the valuable extract to be reintroduced into the brewing process. The hot trub is traditionally separated from the wort in the whirlpool. This forms a trub cone containing valuable wort. Through targeted wort recovery, this liquid is efficiently returned to minimize losses and increase yield.

Processing spent grain and dewatering yeast enables the by-products to be further processed for use in other industries, such as in the production of animal feed or food.

Flottweg offers specialized decanter and Sedicanter® plants and impressive customized technologies. These plants are highly efficient, perform gentle separation and can be easily integrated into existing brewing processes. These solutions help breweries combine sustainability and cost-effectiveness, while ensuring that the quality of their beer remains consistently high.

Centrifuges for Beer Production

Optimization of recovery and processing of beer

When beer is recovered from excess yeast, it is crucial that the extracted beer is of the highest quality and does not compromise taste. Gentle separation of beer and yeast ensures optimum yield and beer quality. Fluctuating yeast concentrations and strict hygiene standards make it difficult to choose the right technologies.

Efficient separation processes are necessary for recovering wort from hot trub. It is important to recover wort with a high liquid content and minimize the loss of this valuable product. The plant must be robust enough to function effectively in hot processes, facilitate a smooth production process and maintain the quality of the wort. Integration into existing brewing processes and savings in waste and energy costs are also crucial factors.

During the processing of spent grain and the dewatering of yeast, the resulting by-products are recovered for use as raw materials in the animal feed or food industries. Efficient dewatering reduces volume, improves shelf life and reduces disposal costs. As a mechanical precursor to thermal drying, it saves energy. Decanters facilitate high separation, retain valuable ingredients in the solids, and improve cost-effectiveness and sustainability.

On the whole, these processes require innovative, flexible and sustainable technologies that help breweries make optimal use of resources, reduce costs, and meet the highest quality standards.

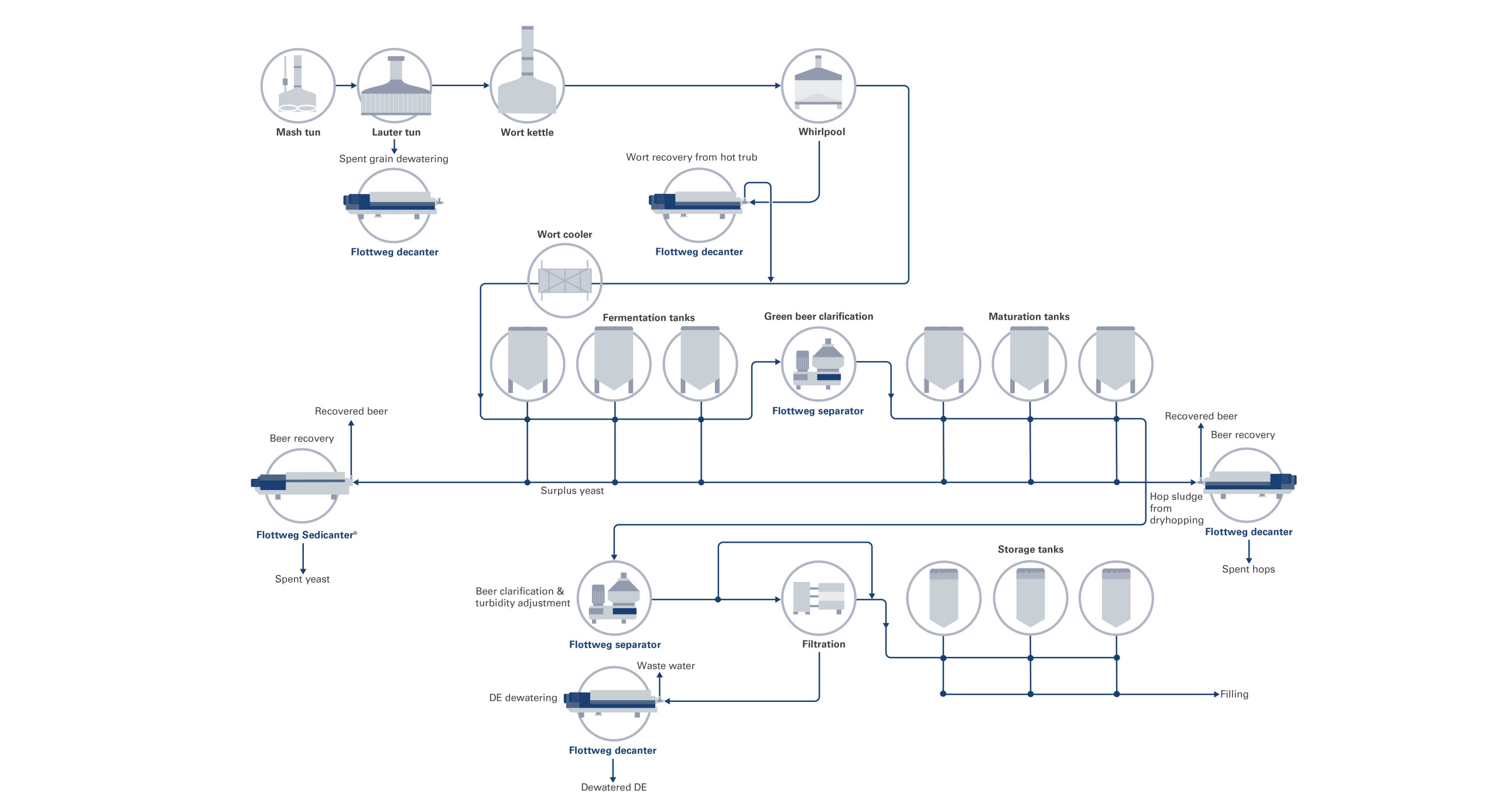

The brewing process with separation technology from Flottweg

Flottweg decanters, Sedicanters® and separators are key products for the efficient recovery of wort and beer in the brewing process. The Flottweg decanter is primarily responsible for wort recovery. It recovers up to 98 percent of the liquid wort from the separated hot trub and returns it to the brewing process. This reduces losses and significantly improves yield.

In the case of dry-hopped beers, the decanter is used in a cold process to remove the hop trub and yeast that have settled in the tank cone. This reduces hop-related losses and significantly increases yield while reducing wastewater. The hop solids are separated with an efficiency of up to 99 percent.

The separation process requires no further dilution, which ensures the high quality of the recovered beer. At the same time, the use of energy and resources is optimized, which offers economic and environmental benefits. The Sedicanter separates yeast with an efficiency of over 98 percent.

Flottweg separators support the optimization of fermentation and filtration processes in later production phases and ensure clear and stable beer quality through reliable beer clarification.

The recovery process using Flottweg plant is designed to be efficient and hygienic, and to integrate easily into existing brewery processes. The robust and hygienic machines meet the strict requirements of the brewing industry in both hot and cold processes. By recovering wort and beer, they facilitate significant savings in raw materials and energy. This is complemented by comprehensive system and process solutions, including compatible peripherals such as valve technology, control systems, and CIP concepts. These features allow for seamless integration into the overall system. Thus, a cost-effective and sustainable solution is created that fully meets the requirements of modern breweries.

Beer recovery from spent hops – Dry Hopping

For craft brewers in particular, the character of their beer is very important. A small change to the taste of the beer can result in a completely different aroma. Unlike industrial breweries, a craft brewery often has less space and production capacity, making it all the more important to get the most out of their existing resources.

The Flottweg decanter system was developed for the efficient recovery of beer from hop trub after dry hopping. Thanks to the impeller and InGo control systems, the system automatically adapts to the feed situation and beer recipes, maximizing yields and minimizing losses.

The system effectively separates hop residues from the beer and returns the high-quality product back into the production process. This increases yield and reduces wastewater pollution – ideal for hop-based beer styles and craft breweries.

Our patented methods and comprehensive process knowledge enable us to offer customized solutions ranging from semi-automatic to fully automatic systems. The system includes all peripheral components for seamless integration into existing brewing processes.

Advanced hop-beer separation

- Up to 99% of the hop particles are removed

- Additional beer recovery from yeast sediment or from alternative aroma sources

- Many years of process expertise with decanter technology in cold processes

High yield

- Precise centrifuge settings facilitate the recovery of up to 97% of the beer volume while achieving excellent dewatering of hop solids.

Plug and play system

- Fully automatable with proven peripherals

- Flottweg enables flexible beer and wort recovery, easily integrated into brewing processes

Recovery of beer from surplus yeast

High-quality workmanship

- The machine design is specially adapted to the high hygiene requirements of breweries

- Integration into the brewery's existing Keller CIP system is simple

Safe and careful processing

- Yeast cake with high dry solids content

- No dilution or reduction of the extract in the recovered beer

Beer recovery from surplus yeast after fermentation or maturing significantly reduces beer waste. The process creates two valuable products Beer that is returned to the production process, and yeast that can be further processed to create a vitamin-rich dietary supplement or animal feed.

The dewatered yeast is optimally conditioned for subsequent processes such as thermal drying or extraction in upcycling applications. This makes the best possible use of beer and yeast, which increases sustainability and cost-effectiveness.

The Flottweg Sedicanter® offers a decisive advantage: it maximizes the dry matter content of the discharged yeast. The centrifuge concept combines a decanter and separator for efficient separation without dilution. Its design allows for easy cleaning in line without the need for additional CIP modules, making it ideal for cold processes.

Wort recovery from hot trub

When the wort, hop residues and precipitated proteins are separated, hot wort comprising up to 98% wort is formed in the whirlpool.

The decanter is designed individually in close coordination with the brewery and customer to ensure optimal separation efficiency. The adjustable impeller allows for adaptation to different recipes and settleable solid content. This ensures maximum yield and efficient wort recovery. The decanter effectively separates hops and trub, particularly in craft beer styles with a high hop content, such as those making use of late hopping. This allows flexible recipe control, optimizes overloaded whirlpools and improves wort quality.

The decanter process shortens the occupancy times in the whirlpool, as separation takes place more quickly. This improves the quality of the wort due to the reduced hot holding time and shortens cleaning times. This reduces water consumption and the number of brews can be increased, which speeds up the brewing process. Compared to disk centrifuges, the decanter works with concentrated trub, which reduces volume, energy consumption and maintenance costs.

Clear wort

- Adjustable impeller for seamless conversion to the requirements of different recipes and hot trubs

- Significant reduction in wort loss

Optimal process management

- Continuous, automatic operation

- Shorter hold time in whirlpool

- Lower production costs per hectoliter of beer

Flexible integration

- Can be integrated with whirlpool or trub tank

Brewers grain processing and Yeast dewatering

Upcycling

- Sustainable recycling saves resources and reduce CO2 emissions

- Hygienic CIP design boosts brewing safety and cleanliness

Cost saving

- Flottweg decanters reduce disposal and transport costs

- Minimizing beer losses increases yield and profitability

Results

- Spent grain dewatering without pretreatment

- Achievement of a separation efficiency of 98%

- Dry solids up to 42%, depending on the composition of the spent grains

The brewers grain produced during beer production often still contains a high proportion of nutrients and protein. This product can be used, for example, as animal feed or as a nutritional supplement. However, it is necessary to dewater the brewers grain as much as possible.

Flottweg's innovative decanter technology can increase the dry solids content to over 35 percent. Depending on the type and composition of the spent grain, it is possible to increase this figure to 42 percent. The Flottweg decanter has a significant advantage over conventional screw presses: it has a separation efficiency of over 98%.

Dewatering significantly reduces the volume, resulting in lower transport and disposal costs. Mechanical drainage precedes the thermal drying processes, in which spent grain is converted into a valuable, storable product. The more effectively the decanter is used, the lower the subsequent costs in the drying process.

Beer Recovery from Spent Hops – Rhinegeist Brewery Relies on Flottweg Decanters

Rhinegeist Brewery—located in Cincinnati, Ohio has increased their beer yields by 10 percent each batch thanks to beer recovery using a Flottweg decanter centrifuge. Cole Hackbarth from Rhinegeist Brewery explains to us the advantages the decanter centrifuge offers for the brewery.

In order to push the brewery’s growth, Rhinegeist had bought a Flottweg disc stack centrifuge a few years ago. Now they also bought a Flottweg decanter centrifuge, which is used for beer recovery from spent hops. Hop sludge which sediments on the tank bottom still contains a considerable amount of high-quality beer, which is, in general, separated before further processing by simply removing it, thus sometimes wasting a significant amount of beer. The Flottweg Decanter separates the spent hops from the liquid beer and uses pressure to return this to storage or bottling, thus considerably reducing beer losses and relieving the load placed on downstream centrifuges and filtration. The new decanter centrifuge sold to Rhinegeist paid off in less than a year.

Benefiting every Flottweg customer

Decades of experience

Flottweg has been passionate about manufacturing centrifuges for solid/liquid separation for over 70 years. With Made in Germany quality, our worldwide customers are always impressed by our expertise.

Individual advising

Our sales team is always happy to provide you with personalized advice. We look at your individual process to guarantee your success.

Dependable service

Even the best machine needs servicing from time to time. We have subsidiaries and representatives standing by around the world to hear your concerns. We are happy to advise you, whenever you need us.

Long-lasting durability

Flottweg machines can be operated day and night for years because they are made of high-quality materials, equipped with numerous practical features, and use technology that sets the global standard.