- Maximum dewatering efficiency with minimal polymer use - cutting disposal costs

- High-quality wear protection ensures reliable operation and easy maintenance

- Up to 20% energy recovery thanks to innovative Recuvane® technology

Dewatering of sewage sludge with Flottweg decanter centrifuges

Efficient, reliable, and cost-effectiveThe actual task of a sewage treatment plant or drinking water treatment plant is to clean the wastewater or untreated water, where sludge is produced as a by-product. After efficient thickening, accompanied by an optimized digestion process, Flottweg decanters ensure efficient dewatering and cost-effective process management as a result. Depending on the individual requirements, Flottweg industrial centrifuges can be used for a wide range of sludge types: SBR sludge, aeorobically stabilized sludge, or classic digested sludge. We can optimize your process even when special requirements exist, such as very low feed concentration <10 g/l. As a transitional solution or for dewatering several small sewage treatment plants, we offer container or mobile systems—also as rental systems—for limited space.

Our decanter centrifuges for sludge dewatering

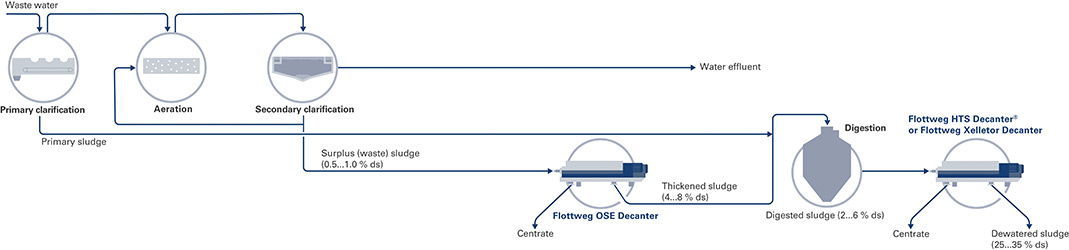

The sewage sludge dewatering process with Flottweg separation technology

Sewage sludge dewatering is an important step in wastewater treatment. Decisive factors for sludge treatment include the dewatering result and the degree of separation in particular. A good dewatering result reduces disposal costs; a high degree of separation reduces reverse contamination This in turn means lower organic costs. And all this with the efficient consumption of polymers, energy, water, and reduced need for maintenance and replacement parts—a continuous, automated operation at minimal cost.

All these success factors have been taken into account at Flottweg since the early seventies. The result of this continuous development is the Flottweg HTS decanter® and Xelletor series for sludge dewatering for throughputs ranging from 5 to 18 m³/h.

Flottweg has developed a unique centrifuge concept specifically for the high-level dewatering of sludge: the Flottweg Xelletor series. This series combines our latest technologies and findings from the field of sludge dewatering.

Overall process for sludge treatment with Flottweg decanter centrifuges

Overall process for sludge treatment with Flottweg decanter centrifuges

Increased effiency

Efficiency and cost savings play a decisive role in all sizes of sewage treatment plants today. The sewage sludge dewatered with a Flottweg decanter achieves optimum dewatering performance. This leads to considerable savings in transport and disposal costs.

Lower resource consumption

No consumable materials such as filter media or filter cloths are required to operate the decanter centrifuges. This makes operation easier and also helps resources to be used in a responsible manner.

Special wear protection

The high forces acting in the centrifuge cause wear and tear on the machine. The wear protection of Flottweg decanter centrifuges reduces wear and tear—affected parts can be easily exchanged and replaced on site.

Highest dry solids with minimum polymer consumption

The right machine for every sludge, but always designed for maximum efficiency! The deep pond concept of all our dewatering decanters ensures substances are gently fed in, thereby reducing the use of polymers and ensuring optimal dewatering. This creates the highest dry solids with minimum polymer consumption.

Easy operation and short downtimes

Flottweg centrifuges for sewage sludge dewatering are designed to be user-friendly and only require minimal downtime. This ensures continuous and uninterrupted production.

Energy efficiency

Energy efficiency is a key lever for Flottweg in the field of environmental sustainability. The centrifuges and systems are designed for optimized, minimal energy consumption. Nearly 20% of the energy used can be recovered with the Recuvane systems in the centrate discharge area.

The right decanters for the thermal hydrolysis process (THP)

Thermal hydrolysis is a process used in sewage treatment plants with anaerobic digestion. Thermal hydrolysis subjects sewage sludge or other organic waste to high temperatures and high overpressure.

Flottweg decanters are used by leading suppliers of THP systems. In preliminary dewatering or pre-thickening of the THP plant, Flottweg decanters ensure the dry solids discharged are uniform and consistent (16.5%–20% DS). Plus the low consumption of polymer flocculants. With modern Flottweg high-performance decanters, optimal results are possible when dewatering the treated sludge with THP and anaerobic digestion.

The Flottweg Xelletor at the Weinheim Sewage Treatment Plant

The Weinheim Sewage Treatment Plant treats the wastewater of 200,000 inhabitants in a catchment area of around 200 square kilometers. The sludge generated during wastewater treatment is fermented into biogas and digested sludge in digesters. The resulting digested sludge is then dewatered using an X5E Centrifuge. In this video, you can find out what this means in terms of costs for the sewage treatment plant.