2023-12-15

A new level of sustainability: Sewage sludge dewatering at Trier's main sewage treatment plant with Flottweg decanter centrifuges

As a pioneer in artificial intelligence and sustainability, Trier's main wastewater treatment plant has focused on the continuous optimization and constant development of its processes for many years. With these in mind, the plant reexamined its sludge dewatering process in 2021. In collaboration with the separation specialist Flottweg, its system was converted to industrial centrifuges. The sewage treatment plant has used Flottweg’s Xelletor machines ever since, helping it to achieve massive cost savings. At the same time, Flottweg's decanter centrifuges ensure the energy neutrality of the entire plant and help to implement innovative approaches.

One of two sewage treatment plants in the city, Trier's main sewage treatment plant processes the wastewater from 100,000 citizens as well as the local businesses and industries. Its primary task is to clean and process the wastewater so that it can ultimately be discharged into the Moselle.

Energy neutrality is the chief concern of this sewage treatment plant. As such, various measures have been implemented since 2013 in order to achieve a positive energy balance: "As early as 2013, we began to look at and rethink our existing processes," explains Wastewater Treatment Plant Manager Marius Barbian, who is responsible for operating both wastewater treatment plants in Trier. "We installed photovoltaic panels on the roofs, integrated a discharge turbine, use artificial intelligence, and utilize the sewage gas in our CHPs." By doing all of this, the sewage treatment plant was able to incrementally implement sustainability in conjunction with innovation. As a result, operation of the sewage treatment plant has been energy-neutral since 2016.

The main sewage treatment plant in Trier is a pioneer in the fields of sustainability and AI.

The main sewage treatment plant in Trier is a pioneer in the fields of sustainability and AI.Artificial intelligence playing an important role

The use of artificial intelligence is especially helpful when it comes to energy neutrality: Data from the existing process control system is evaluated by the AI using a self-learning, intelligent algorithm. This allows various processes to be adapted and optimized with respect to energy efficiency. "We installed an AI to give us optimal control of the sewage treatment plant back in 2017. Thanks to this AI, we are now able to save over 300,000 kilowatt hours of electricity per year while also operating our wastewater treatment more efficiently. Using less electricity and therefore generating less CO2 is the biggest gain for us," Barbian explains. By using AI in its sewage treatment plant, Trier is pioneering the way with continuous development of this technology in recent years.

Marius Barbian is wastewater manager at the main wastewater treatment plant in Trier.

Marius Barbian is wastewater manager at the main wastewater treatment plant in Trier. By 2021: Sewage sludge as major cost factor

After completing various modernization projects, the disposal of sewage sludge finally became the focus in 2019: After stabilization in the digesters, the resulting sewage sludge, which comes to approx. 40,000 tons per year, was discharged into sludge holding tanks where it settled naturally. The sewage sludge was then spread over fields as fertilizer, but this resulted in high costs for the sewage treatment plant. So that it could operate as cost-efficiently as possible, in 2019 Trier's main sewage treatment plant decided to build a mechanical sewage sludge dewatering system in order to dewater the resulting sewage sludge on its own.

Trier looked at various processes during the planning phase. In the end, the decision was made to use a sewage sludge dewatering process with centrifuges: "We asked ourselves: Do we want to use centrifuges or screw presses? Since the main sewage treatment plant has a relatively high degree of automation, one thing quickly became clear to us: Centrifuges must be used. We then looked for a strong partner that we could rely on," says Wastewater Treatment Plant Manager Barbian.

Trier uses a C4E for its surplus sludge dewatering system, which has been in operation since 2016: "For us, the greatest advantage of our existing Flottweg machine is that we can run it 24 hours a day, 365 days a year. We have had no issues or major repairs since it was commissioned, and it is still in operation today."

Following its successful tender, the decision was ultimately made to choose Flottweg again. A new dewatering building was also built for the sludge dewatering process in order to provide sufficient space for necessary machinery and systems.

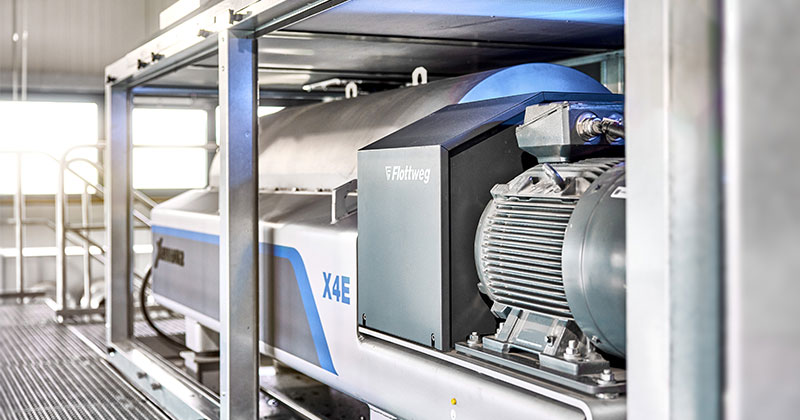

Two Xelletor X4Es are used for sludge dewatering at the main wastewater treatment plant.

Two Xelletor X4Es are used for sludge dewatering at the main wastewater treatment plant."Both machines ran smoothly from the very first second"

Since 2021, Trier's main wastewater treatment plant has used two Xelletor X4Es with a maximum throughflow of 800 kilos per hour per machine. Marius Barbian is very satisfied with the decision to choose Flottweg: "From the very first moment, we had absolutely superb results from these machines, which we were able to integrate perfectly into our process. We didn’t have any room to maneuver when we switched from wet sludge production to dewatering. We basically had to have one working machine from one day to the next, and both of these machines ran smoothly from the very first second." This is an important aspect to consider, as it ensures that the main sewage treatment plant's work proceeds smoothly, and that it is able to seamlessly integrate the sludge dewatering system into its daily work.

Because of the sewage treatment plant's high degree of automation, the adaptability of the two Xelletor decanters is also a convincing factor: "To be able to use a machine in a truly sustainable way, we need machines that we can control ourselves for every process. With Flottweg machines, we can make all the small adjustments on our own, be it the bowl speed or something else. This enables us to then aim for an optimal operating time that is efficient in terms of technology as well as energy consumption." For Barbian, this is a crucial point both in terms of the sewage treatment plant's desired degree of sustainability and with respect to the employees who use the system every day. This ensures that they are able to identify with the overall process.

The two decanters are fitted with noise protection hoods to make the working atmosphere as pleasant as possible.

The two decanters are fitted with noise protection hoods to make the working atmosphere as pleasant as possible. For reasons of occupational safety, Trier's main sewage treatment plant also decided to enclose the machines, which keeps noise levels as low as possible. As a result, the working atmosphere in the new dewatering building is as pleasant as possible for all employees and meets current work standards.

Trier's main sewage treatment plant benefited not just from the machines themselves, but also from Flottweg’s service: "Because Flottweg's production is located in Germany, it offers incredibly fast and flexible spare parts delivery and support." For Barbian and Trier's main sewage treatment plant, this is essential for preventing long downtimes. One aspect that was already known since purchasing its first decanter for dewatering surplus sludge: "We have been satisfied with the service, durability, and low maintenance costs of our Flottweg machines since 2016. Our previous experience was also confirmed with the new Xelletor machines."

Dialog, important for innovation and further development

Conducting numerous tests and trials, the sewage treatment plant has gained experience in the areas of sustainability and AI in recent years. However, Trier's sewage treatment plant does not just want to keep this knowledge to itself, it wants to share this knowledge by speaking with other operators. This is a topic that is close to Barbian’s heart: "We look forward to sharing ideas with other wastewater treatment plants and are ready to pass on our knowledge. By doing so, we want to get rid of the fear associated with new technologies and demonstrate how AI, etc. can be integrated in a targeted manner." In Barbian’s view, this dialog and exchange makes further development possible with regard to innovation and sustainability.

Author:

Julia Deliano, PR & Content Manager at Flottweg

Watch the whole video

You would like to know more about our solutions for waste water treatment plants?

Talk to us or write us!