2025-10-22

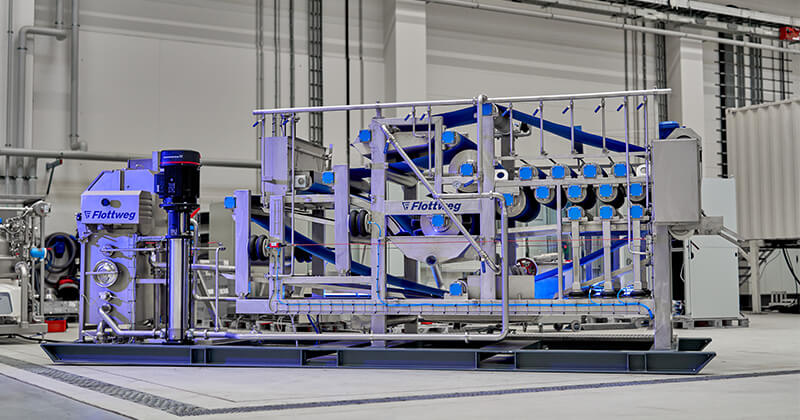

Efficiency and quality: an interview with Daniel Obrist about the Flottweg belt press

It is very important for our customers that the belt press works efficiently. First and foremost, a high yield is important. In addition, efficiency for the customer means that they need few operating personnel, which reduces costs.Daniel Obrist Daniel Obrist is working for Flottweg since 24 years. For over a year, I've been working as a Sales and Application Manager in the fruit juice division .

From juice to starch to vegetable milk substitutes—the belt press is a true and comprehensive all-around machine for the food and beverage industry. In an interview, Flottweg Global Sales and Application Manager Daniel Obrist explains the wide range of applications, the functions and the advantages of belt press technology. He also explains why hygienic design is so important for the belt press and how it relates to efficiency.

In which areas of application can the belt press be used?

Our belt presses can be used in a wide variety of applications. They are mainly used for fruit juices and vegetable juices, but they are also used in other applications such as potato starch, soy, brewer’s grains, coconut or plant-based milk substitutes for the best possible dewatering.

How does Flottweg’s belt press work?

The product is fed via the feed hopper of the belt press. This can be done by means of a pump, conveying units or by direct treatment. The product is then continuously and uniformly conveyed out of the feed funnel by the feeding roller. The product then runs between the two filter belts over the elbow zone, where the first dewatering already takes place, further into the press roller area starting with the L-profiled roller and then into the high-pressure area.

Depending on the applications, our belt press can be fitted with different press nip rollers to respond flexibly to different products and requirements.

What are the benefits of the belt press for the customer?

Flottweg belt presses have the advantage for the customer that they are efficient, intuitive, easy to clean and therefore cost-effective to operate. The belt press extraction system, the hygienic design and the low costs concept of Flottweg’s belt press are important features that make these advantages possible.

What is special about the extraction system of Flottweg’s belt press?

The special feature of our belt press extraction system is continuous and optimal dewatering in our machine. This results in the highest yield for our customer.

In particular, Flottweg’s belt press extraction system is characterized by a two-belt press configuration. The product is passed between two filter belts. Due to different roller diameters, larger and smaller, the pressure and shearing force in the machine are continuously increased. This ensures the maximum, best possible dewatering of the products to be processed.

In addition, with our belt press, the product is processed quickly, and the machine is adaptable to a wide variety of products.

There are a wide variety of configurations – from the feeding rollers to the distributor screws and the press roller area. The machines are optimally adapted to the respective application for the best possible result.

The cleaning of the belt press is hugely significant, particularly in the processing of food. Why is this so important?

For the customer, cleaning the belt press is very important for achieving the highest possible product quality. For this reason, the hygienic design of the belt press plays a key role.

Flottweg belt presses have a belt cleaning system in circulation. This ensures that the belts in the feed area of the belt press are always clean. This is very important to dewater the product to an optimal degree while also ensuring the highest quality.

How did Flottweg implement the hygienic design for the belt press? And what is the advantage?

Hygienic design was incorporated into the development of the belt presses from the very beginning. Flottweg’s belt press is easily accessible, easy to clean and you can also perform a visual inspection at the end. In addition, depending on the customer’s wishes, CIP cleaning can be integrated into the belt press. In addition, for the hygienic design of our belt presses, all sheet metal parts, from the rollers to the frame, are made from high-quality stainless steel.

A major advantage of our belt cleaning system is its low water consumption. Fresh water purification is often used by other manufacturers, where a large amount of fresh water is required. In Flottweg belt press plants, the belt washing water is circulated, cleaned via mesh with only a small amount of fresh water required. That, too, is a form of efficiency.

In addition, we use a pneumatic system for the belt tension and for belt alignment control. This has the advantage that, in contrast to other systems which work with hydraulic oil, the product cannot be contaminated. Especially in the food and beverage industry, this is a relevant point to prevent endangering product quality.

What does efficiency mean in the context of the belt press?

It is very important for our customers that the belt press works efficiently. First and foremost, a high yield is important. In addition, efficiency for the customer means that they need few operating personnel, which reduces costs. Simple maintenance and low energy consumption also have a positive impact on operating costs. Cleaning plays another important role relating to efficiency.

In conclusion, the efficiency of our belt press systems is determined by various aspects. The combination of these factors makes our belt press an excellent choice for customers who value quality, sustainability and cost-effectiveness.

At Flottweg, we pride ourselves on bringing these high standards together in our products which offers real added value to our customers.