- Up to 50% dry substance through innovative decanter technology

- Integrated cleaning systems and FDA-compliant materials ensure premium product quality

- 24/7 automated operation for maximum production efficiency

High quality and pure yield

Flottweg decanters and separators for the production of casein

With a proportion of around 80 percent, casein is the main protein in cow’s milk and plays a crucial role in various industrial sectors. It is used in the chemical industry for paper production as well as in the food industry as a high-quality protein. Centrifuges are an essential part of the industrial production and manufacture of casein. They enable efficient production with a high total dry solids content in the end product and contribute to sustainable casein manufacture through their water-saving process.

Our centrifuges for casein extraction

How does the casein production process work in the dairy industry?

1. Step

Casein production begins with a well-defatted skimmed milk. This represents the raw material for the extraction of milk protein.

2. Step

Casein is precipitated by adding rennet or mineral acid.

3. Step

The casein is washed and concentrated in several washing stages.

4. Step

Separators can optionally be used for further polishing and recycling of the whey and wash water.

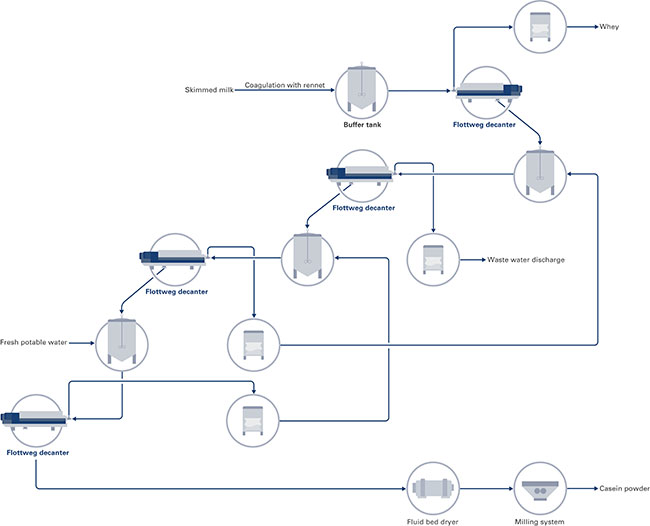

Manufacture of casein by rennet precipitation

The rennet casein is obtained by enzymatic precipitation... Enzymes, such as chymosin and rennet, thicken the pasteurized skimmed milk. After deactivation of the enzymes, the coagulated casein is separated from the whey by the decanter. In several washing steps, the casein is repeatedly washed and dewatered using the water-saving counterflow principle. In a final decanting step, the casein is separated with a dry substance of up to 50%.

Process for the manufacture of casein by rennet precipitation

Process for the manufacture of casein by rennet precipitation

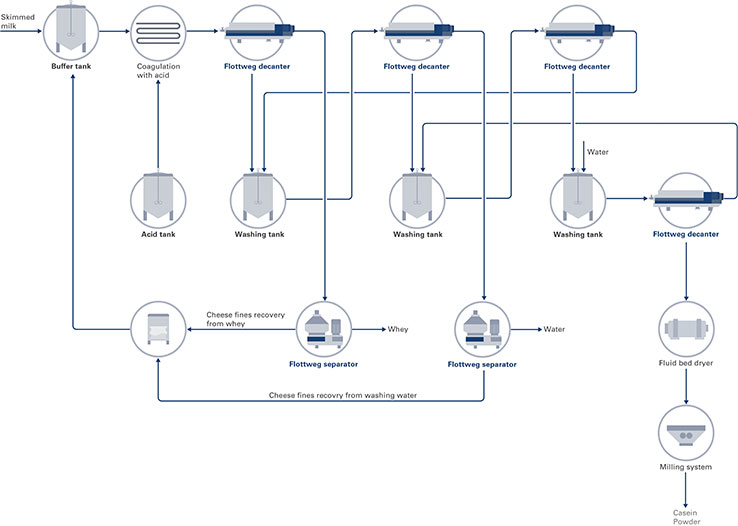

Manufacture of casein by acid precipitation

In contrast to rennet precipitation, acid casein is extracted by acidifying the skimmed milk to its isoelectric point. This can be done with both biological and mineral acids. Acidification neutralizes the negatively charged casein micelles, resulting in precipitation of the casein. Analogously to the rennet precipitation process, the casein is separated from the whey, followed by a multi-stage decanter washing process. Both the whey and the wash water are dedusted again via the integrated separators to ensure maximum casein yield.

Process for the manufacture of casein by acid precipitation

Process for the manufacture of casein by acid precipitation

Your advantages in the production of casein

Optimized operation

Flottweg machines are not only characterized by an intelligent design, but also by the InGo user interface. This simplifies the induction training for new employees using the machine, while also providing immediate access, at any time, to the machine data required for your production process.

Quality and hygiene

Flottweg knows the challenges its customers face and ensures optimal product quality by using high-quality materials. The housing and rotor design meet the requirements of a CIP-capable plant. Numerous spray nozzles for cleaning the housing and scroll body support the cleaning capability. The product-wetted seals are made of FDA-compliant material.

Maximum convenience

Do you need continuous operation 24/7 without supervision? Flottweg centrifuges run autonomously and thus help to increase productivity.

Highest yield

Flottweg centrifuges ensure the best dewatering results thanks to their high g-forces: Forces of up to 4,622 g are possible. In addition to higher throughput rates, this also enables better separation to be achieved.

Always at the process optimum – adjustable impeller

In a closed system, the clarified liquid phase can be discharged from the bowl under pressure via an adjustable impeller. The advantages of this technology are clear: Flexible balance between maximum DS content and as pure a centrate as possible. The resulting pressure also prevents the liquid from foaming.

Customized solutions

In addition to the premium quality of our separation solutions, we support our customers with comprehensive advice and laboratory tests. We also offer pilot trials to determine the exact machine configuration, commissioning at the customer’s site as well as process optimization and integration into the overall plant.