- Up to 50% higher surimi yield with German-engineered decanter technology

- Fully automated processing reduces costs while ensuring consistent quality

- Hygienic design meets strictest standards with stainless steel construction

Surimi Manufacture Using The Decanter

Surimi processing is a meticulous procedure that transforms fish into a versatile protein base through the following steps:

1. Fish Preparation:

Fish are categorized by size and then undergo a thorough cleaning process, including the removal of heads, viscera, skin, and bones. The fish are then filleted, and the fillets may be processed through a meat separator or deboner.

2. Mincing:

The cleaned fish fillets are minced, and any remaining bones are mechanically removed to ensure a pure product.

3. Washing:

The minced fish is washed multiple times (typically 2-3 cycles) with a ratio of mince to water of 1:3 to eliminate impurities like blood and fat.

4. Refining:

Any residual waste or small bones are discarded to refine the surimi.

5. Dewatering:

The washed mince is dewatered using methods such as manual presses, nylon mesh bags, centrifugation, or screw presses to reach the ideal moisture content of 80-84%.

6. Adding Cryoprotectants:

Cryoprotectants are mixed in to protect the surimi during freezing.

7. Packaging:

The surimi is packaged in a manner that preserves its quality.

8. Freezing:

Finally, the surimi is frozen, stabilizing its shelf life for future use in various culinary applications.

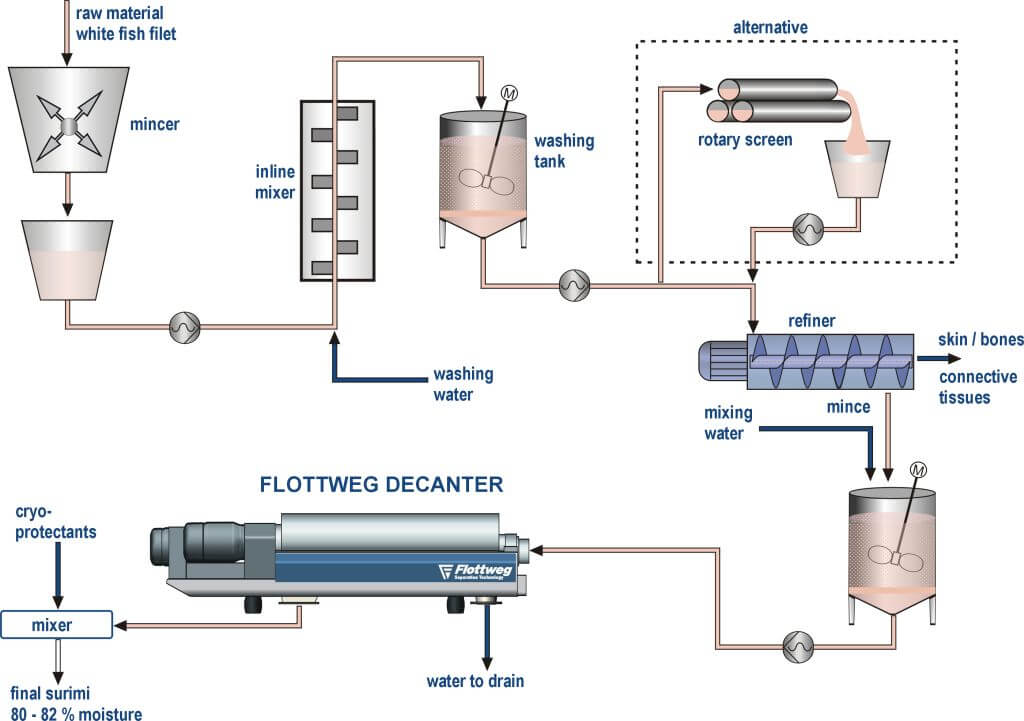

The manufacture of surimi involves washing a minced fish filet in a two or three-stage process. Impurities such as blood and fat are removed in this process. Normally, a rotating screen provides superficial cleaning of the wash water.

In conventional production of surimi, screw presses dewater the minced fish meat. Then it is treated with anti-freezing agents before being deep frozen.

This Manufacturing Process for Surimi Offers Numerous Disadvantages

- High losses of meat fibres during the various stages of washing and in the screw press

- Significant wash water consumption

- High space requirement for the systems

- Easy perishability of the raw material

Flottweg decanters are the solution to all these problems. In the production of surimi, decanters can be used for recovering the meat fibres from the wash water and/or as a replacement for the screw presses. This significantly increases the yield of surimi during the manufacturing processes.

The Flottweg Decanter offers numerous advantages in the production of Surimi:

- Up to 50% higher overall yield compared to conventional surimi manufacture for fibre recovery from the wash water or replacement of the screw press

- Consistent residual moisture in the end product because of the Flottweg Simp-Drive®

- Reduction in operating costs because the manufacturing process for surimi is fully automatic

- High flexibility in order to meet different market requirements

- Ease of operation, even with fish species that are difficult to process

- Cleaning programs for optimum CIP cleaning

- Careful product processing leads to very low product heating

The Flottweg decanter for surimi manufacture

The Flottweg decanter for surimi manufacture

Flottweg - Your Partner for Surimi Manufacture

Flottweg knows the exacting requirements of the fish industry. We have more than 50 years of experience in separation technology, and are specialists in the manufacture of surimi. Take advantage of our knowledge, experience and expertise:

- Hygienic design: All components that do come into contact with the product are made from corrosion-resistant stainless steel, and meet the most exacting hygiene standards

- Individual support: We find the right solution for your process

- ISO certification: Flottweg is certified to ISO 9001 and builds its products according to the latest technical standards

- Made in Germany: All Flottweg decanters are produced in Germany by specialist technician