2023-11-03

Sustainability from A to Z — Use of Flottweg Industrial Centrifuges at the Bergstraße Wastewater Association in Weinheim

The Bergstraße Wastewater Association in Weinheim, which is located around 17 kilometers northeast of Mannheim, processes 24,500 m³ of wastewater every day. The topic of sustainability is very important for the wastewater association. The sewage treatment plant is always looking to find new and especially efficient solutions to treat wastewater. That's why its modernization measures started focusing on sludge dewatering in 2016. With Flottweg machines, the Wastewater Association managed to find an efficient and environmentally friendly solution that also makes it possible to cut costs significantly at the same time.

Wastewater from eight cities and municipalities in Hesse and Baden-Württemberg is transported to the Bergstraße Wastewater Association in Weinheim every day. The wastewater association currently processes the wastewater of around 200,000 inhabitants and has a catchment area of 200 square kilometers. In addition to treating wastewater, other central tasks of the wastewater association include sludge treatment and biogas production. To do this, a mechanical wastewater treatment system, a biological treatment system, and secondary clarifiers are all used. Sludge generated during the process is fed into the digesters. The digested sludge is then fermented before it must also be dewatered. Finally, the treated wastewater is discharged into the Weschnitz tributary.

Sustainability is an important issue for the Bergstrasse Wastewater Association in Weinheim.

Sustainability is an important issue for the Bergstrasse Wastewater Association in Weinheim. Sustainability—More than Just a Buzzword

Sustainability plays an important role for the wastewater association. Manuel Ritter, the wasterwater association's wastewater manager who is in charge of process engineering and wastewater treatment at the sewage treatment plant, states: “The topic of sustainability is very important to us. For many years now, we’ve been trying to make our sewage treatment plant sustainable and efficient through a variety of modernization measures. The subject of energy consumption in particular has kept us busy for a lot of that time.” This focus on energy consumption is the reason why the wastewater association consumes around 19 kilowatt hours of energy per inhabitant per year, whereas other sewage treatment plants consume an average of around 30 kilowatt hours of energy per inhabitant per year. The eight cities and municipalities also benefit greatly from this aspect when it comes to costs. In order to further promote sustainability, the company also covers its own electricity needs with three CHP plants and reuses the heat generated to heat the buildings and digesters. The wastewater association’s energy efficiency is further facilitated by the solar energy generated by the photovoltaics on the roofs of the sewage treatment plant buildings, which cover an area of approximately 5,000 m2 .

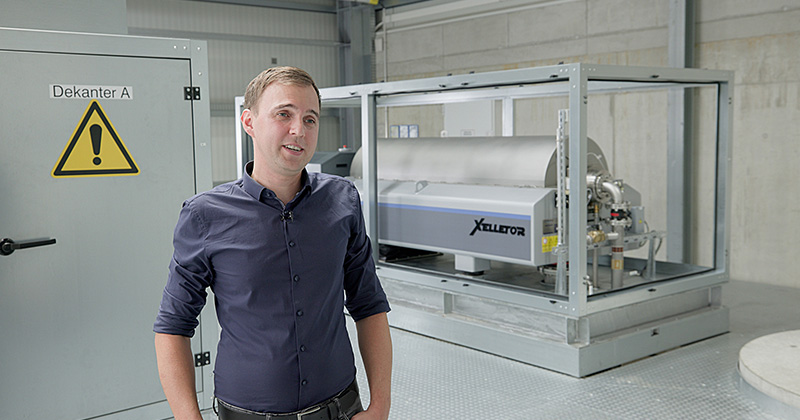

Wastewater master Manuel Ritter coordinated the modernization measures at wastewater treatment plant in Weinheim.

Wastewater master Manuel Ritter coordinated the modernization measures at wastewater treatment plant in Weinheim.

Within the context of all these measures, the wastewater association also refocused its sustainability measures on sludge treatment in 2016. Chamber filter presses which had become outdated over the years were used in the treatment of sludge. “The costs of operating and maintaining the machine were not only very high, but the power throughput of the chamber filter presses was no longer adequate for the population values,” explains Wastewater Manager Manuel Ritter. "At the same time, the consumables and auxiliary materials for the machine were also very high, making sludge dewatering very expensive for the wastewater association." The sewage treatment plant decided to modernize its sludge dewatering system to ensure the most cost-efficient operation over the long run. The wastewater association took various methods into consideration for the new sludge dewatering system in order to replace the chamber filter presses, which were no longer be used in process engineering due to all the uncertainties associated with them. It was also important to find a process that uses the right system components necessary to achieve sustainability-related savings and use energy efficiently.

Proven Successful

Based on positive past experiences with rental centrifuges, the wastewater association decided to carry out initial tests with centrifuges, including those from Flottweg. Trial runs are an important prerequisite for the wastewater assocation to pretest which method is most suitable for the plant. “We never opt for aggregates or machines where we don’t know that we can confidently implement them in our process,” states Manuel Ritter.

The findings from the trials with Flottweg astonished many at the wastewater association: According to Wastewater Manager Manual Ritter, “The actual results achieved with the Flottweg machines were far better than the results obtained with previously used rental machines.” "We were also able to try out a wide range of flocculants, gather first impressions of the machine, carry out performance tests, and examine the entire process. In addition to Flottweg’s extensive documentation on this trial, we had the opportunity to draw our own conclusions."

After extensive tests, Flottweg machines were selected as suitable separation units for the Bergstraße Wastewater Association.

After extensive tests, Flottweg machines were selected as suitable separation units for the Bergstraße Wastewater Association.Competent Contact Persons Always Available

Since 2022, the wastewater association has been using two Xelletor X5E machines to dewater sludge. The wastewater association deliberately opted for a larger separation unit with an output of up to 70 m³/h to ensure sufficient power reserves for the future. Manuel Ritter looks back positively on the decision to go with Flottweg: “We are very satisfied with the performance of the two machines. They run smoothly, reliably, and fully automatically." The entire commissioning of the two X5E machines also went well without any malfunctions or downtimes. In fact, the entire process—from finding ideas, procuring the machine to implementing the project—also went off without a hitch. “We always felt well looked after, and there was always a competent contact person available,” explains the wastewater manager of wastewater association.

Flottweg’s Xelletor stands out in particular thanks to its separation efficiency and dewatering performance. As the trials already suggested, the modernization of sludge dewatering is now delivering positive results. For instance, the energy required to dewater sludge and the operating times have already been significantly decreased. Flottweg’s high-performance centrifuges consume less power than the old chamber filter presses. The need for flocculants was simultaneously decreased by up to 20%. These are all aspects that have led to measurable cost savings for the sewage treatment plant. The dewatering performance of the Xelletor machines is also impressive and enables the wastewater association to further cut costs associated with sludge removal. The costs of transporting and disposing the dewatered sewage sludge in particular make up a large share of the operating costs.

The two X5Es from Flottweg - without (front) and with (back) acoustic hoods.

The two X5Es from Flottweg - without (front) and with (back) acoustic hoods.

In addition to sustainability, occupational safety plays an important role at the wastewater association. Although the chamber filter presses were dirty and required a lot of work, all the latest work standards and safety guidelines had to be implemented within the modernization measures. As a result, two X5E acoustic hoods were installed to ensure the best possible indoor climate and working conditions. Noise emissions were thus consciously reduced. The modernization measures also simplified the process on site, freeing up more time for employees to do other activities.

The acoustic hoods can be removed in just a few steps.

The acoustic hoods can be removed in just a few steps.The Right Step Toward Sustainability

“For us, Flottweg was the right partner to improve the sustainability of sludge dewatering,” says Manuel Ritter. The wastewater association has taken further steps toward becoming sustainable through its modernization measures and by opting to dewater the sludge with the high-performance centrifuges from Flottweg. "We're not quite done yet—after all, the topic of sustainability is multifaceted and can be achieved in many ways. We will continue our efforts to make the sewage treatment plant as efficient and sustainable as possible. The next steps are already being carried out."

Author:

Julia Deliano, PR and Content Manager, Flottweg SE

Watch the whole video

Would you like to know more about our solutions for waste water treatment plants?

Talk to us or write to us!