- Maximum separation efficiency with advanced disc stack centrifuge technology

- Reduces energy consumption by 75% compared to conventional harvesting methods

- Achieves 25% dry substance content for optimal algae processing efficiency

Harvesting algae cultures more efficiently

algae are all-purpose: algae is suitable as raw materials for food, biofuels, pharmaceuticals, cosmetics and more. In order to optimize the yield of raw materials, manufacturers need state-of-the-art harvesting technology. “Enalgy” stands exactly for this, the highly efficient, cost-saving algae harvesting with Flottweg's separation technology.

Due to their positive attributes, algae are increasingly used in coal production to reduce CO2 emissions and in sewage treatment plants to reduce high nitrogen and phosphor levels. This green bioresource grows in culture ponds or in photobioreactors. During the harvesting, algae are separated from their culture substrate and processed further to become a high-quality concentrate. The harvesting technology used has a decisive influence on the efficiency of the overall process: The aim is to keep both the investment costs and the operating costs for energy, water, etc. as low as possible. At the same time, for optimal processing, the separated algae concentrate should have as high a dry matter content as possible.

The Flottweg "enalgy process" offers a comprehensive solution for these algae harvesting requirements. In principle, two processes are possible, each using a high-quality Flottweg centrifuge: A single-stage process with a Flottweg separator is suitable for small to medium-sized operations. Companies working on a larger industrial scale benefit from a two-stage process in which the Sedicanter® from Flottweg takes over the actual cell harvesting after pre-concentration.

Our industrial centrifuges for algae harvesting

Customer Benefits

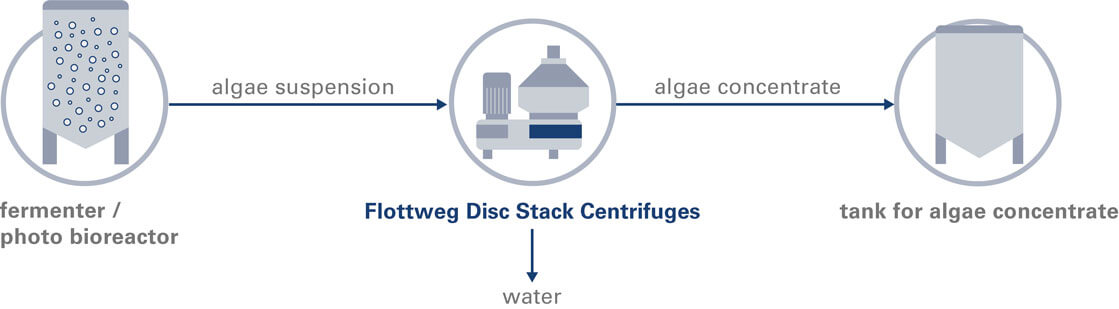

Algae harvesting with the Flottweg Separator

The algae suspension flows from the photobioreactor directly into the Flottweg Separator. Then the distributor gently accelerates the suspension to full speed. Due to the high centrifugal force of up to 12,000 g, the separator dewaters the algae suspension producing an algae concentrate with creamy consistency. Thus making the algae concentrate ideal for further processing. Small to medium-sized plant benefit in particular from the low investment and low operating costs of the single-stage process.

- up to 25 percent lower investment costs

- lower costs for further processing or drying due to a very high-quality algae concentrate

- suitable for medium and small businesses

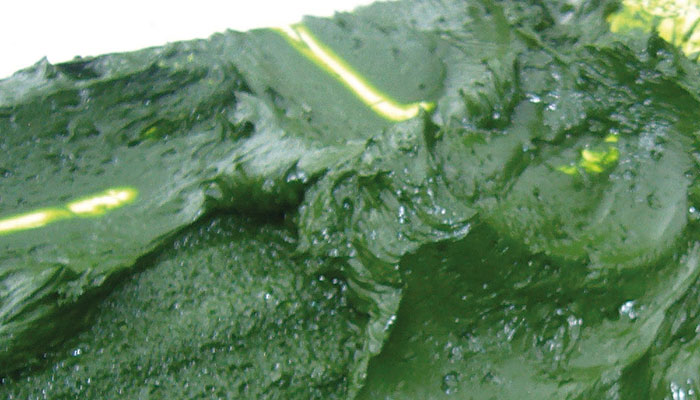

Algae concentrate after processing with the separator

Algae concentrate after processing with the separator

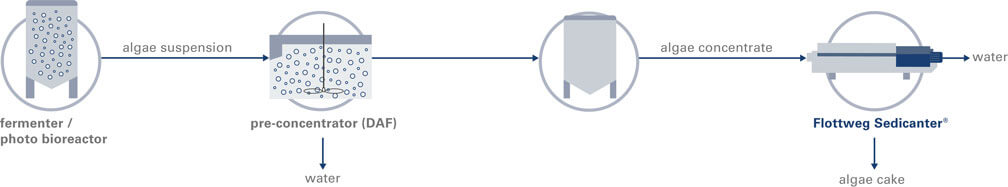

Algae harvesting with the Flottweg Sedicanter®

Algae harvesting with the Sedicanter® is a two-stage process that is ideal for larger operations: The algae suspension from the photobioreactor is initially pre-concentrated. The algae concentrate then flows on into the Flottweg Sedicanter®, where the cell harvesting takes place. The Sedicanter® dewaters the algae concentrate to a compact cake with 22 to 25 percent dry substance content. Only this special decanter centrifuge is capable of thickening the fine and soft algae cells in such an efficient way.

The pre-concentration in the two-stage process saves energy when compared with single-stage processes. The more water that is separated beforehand, the less the Sedicanter® has to separate.

- up to 60 percent lower operating costs (e.g. energy)

- up to 25 percent lower investment costs

- 22 to 25 percent high dry solids content for optimum further processing

Algae dry substance after processing with the Sedicanter®

Algae dry substance after processing with the Sedicanter®

„More than just Greenwashing“

Test results confirm that algae are also suitable as a source of renewable energy: The total energy balance for different harvesting processes was compared in the example.

The Sedicanter® from Flottweg reduces the energy required to harvest algae by 75 percent when compared with conventional processing.

Article in the trade magazine Mitteldeutsche Mitteilungen