- Powerful and robust belt presses for maximum yield

- Hygienic and low-maintenance stainless steel design with automatic cleaning and belt tracking

- Easy-access design for easy maintenance and operation

Hygienic design meets maximum yield: The Flottweg belt press

Efficient solids processing system for the highest requirements in the food industryBelt presses offer proven technology for the effective dewatering of mash, pomace or grape marc. They reliably separate materials into their liquid and solid components. In the food industry in particular, fast, reliable, and hygienic processing is a decisive criterion for preserving valuable ingredients.

The Flottweg belt press effortlessly meets these requirements and ensures outstanding juice quality, particularly in the manufacturing of fruit and vegetable juices. Its performance is impressive, as is its hygienic design: It is made of stainless steel and is equipped with an automatic belt cleaning system that operates during production. A CIP system is featured on all machines. These measures ensure maximum cleanliness and efficiency.

The belt press is indispensable in the manufacturing of starch or plant-based milk alternatives, as it achieves a high dry solids content and significantly reduces transport and total drying solids costs. A belt press is typically part of a multi-step process. Belt presses often interact with other processes, such as those involving decanter centrifuges.

Flottweg offers the optimal solution for every process requirement and supports customers in the selection and integration of manufacturing facilities. The Flottweg belt press features a hygienic stainless steel design, efficient dewatering processes, and low maintenance costs. It ensures optimal, resource-saving production with high yields.

The application areas of the Flottweg belt press

How the Flottweg belt press works

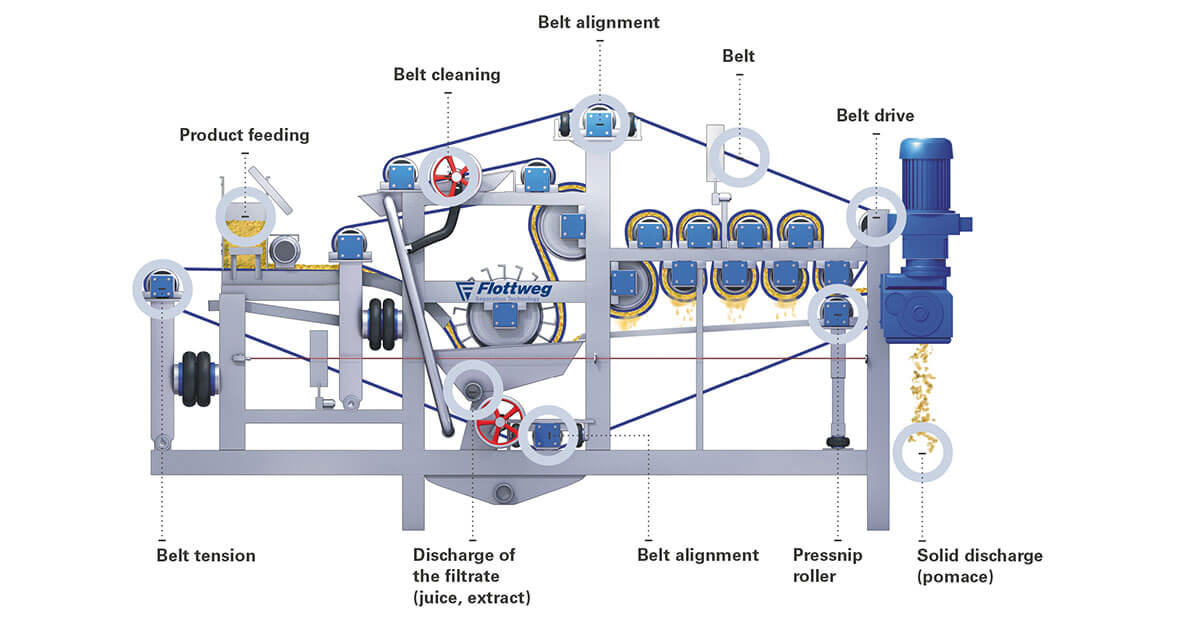

A feed roller distributes the mash continuously and evenly on the lower belt. The cake height and width can be flexibly adjusted to the respective product to ensure optimal product infeed. Various feeding systems ensure precise dosing and even distribution of the mash.

In the wedge zone, the two belts come together. The upper belt applies slow and even pressure to the product, resulting in a stable mash cake. This coordinated press zone facilitates a gentle increase in pressure, which causes the different mash structures to be dewatered gently and effectively.

Dewatering is performed in the press area, initially by an L-profile roller. The roller ensures rapid liquid drainage from both sides of the cake.

Press rolls with different diameters follow. The product is efficiently dewatered through a combination of continuously increasing pressure and shear forces. Optionally, press nip rollers can be used to further optimize dewatering, achieving an even higher yield. During operation, after removal of the pomace, high-pressure nozzles continuously and reliably clean the filter belts of residues, ensuring stable, continuous operation.

VOG Products relies on Flottweg technology

Product features of the Flottweg belt press

Optimal drainage and yield

The press rollers ensure the best possible dewatering of the mash. The mash cake is subjected to a steady increase in pressure by rollers of varying diameters. This facilitates a rapid and efficient juicing process.

The Flottweg Extraction System supports this process with its sophisticated design: An L-profile roller ensures efficient and even centrate discharge, resulting in fast dewatering, a high yield, and top-quality products.

Special press nip rollers, such as edge zone rollers, increase the pressure at specific points and optimize dewatering. This is especially beneficial for special products such as brewer’s grains. The belt alignment brings the belts together in the wedge zone and then guides them over the L-profile roller and the press rollers.

The combination of belt alignment and shear force creates drainage channels that ensure efficient centrate removal.

The two-belt press achieves a significantly higher yield than the single-belt press because products are dewatered more efficiently. This results in a dry solids content of 30% or higher. Specially designed pressing zones, such as the wedge zone and the high-pressure pressing zone, ensure a slow increase in pressure, allowing juice to be extracted gently and effectively from the various structures of the mash.

A flexible feed system distributes the product evenly across the entire belt width. Extensive experience contributed to optimizing this process, further improving the dewatering process.

Health and safety

The Flottweg belt press features a safe and hygienic design. It meets the highest standards of durability, operational reliability, and cleanliness. The entire machine, including rollers and bearing brackets, is made of stainless steel.

Compared to conventional presses, where rollers are often plastic-coated, the consistent use of stainless steel facilitates easier and more thorough cleaning.

The pneumatic belt tension and tracking system uses compressed air instead of hydraulic oil, eliminating the risk of product contamination. Automatic CIP cleaning can be installed as an option. The open design of the belt press ensures good visibility and easy accessibility so that the cleaning process can be easily inspected at any time.

During operation, after removal of the pomace, high-pressure nozzles continuously and reliably clean the filter belts of residues, ensuring stable, continuous operation.

Total Cost of Ownership

Thanks to an intuitive and automated control system, the Flottweg belt press can be operated safely and efficiently with minimal personnel effort.

An integrated recirculation system collects the process water produced during cleaning and reuses it several times, reducing fresh water consumption.

Service costs also remain low, as the belt press is equipped with only a few durable bearings and standardized replacement parts. This makes it much easier to maintain compared to hydraulically operated tank presses. Energy consumption is low thanks to an efficient drive motor with a maximum output of 1.5 – 5.5 kW, which further reduces operating costs.

The robust belt press is designed for a long service life and around-the-clock continuous operation. Optional functions, such as automatic grease lubrication, further increase the ease of facility maintenance. Thanks to the continuous working process, the belt press can process large quantities while coping with production peaks.

The Flottweg belt press is an efficient, cost-effective solution characterized by simple operation and high process reliability. Operating and maintenance costs are reduced to a minimum.

Optimal dewatering

- L-profile roller: Discharges centrate efficiently and evenly

- Press nip rollers: Increases pressure at certain points for better dewatering

- 2-Belt press: Achieves higher yield (75–85% total dry solids)

Flexible adaptation thanks to Flottweg Extraction System

- Coordinated press zones: Slow pressure increase allows gentle dewatering

- Flexible feeding system: Wide application of the solid cake, optimized by experience and trials

Hygienic design and easy cleaning

- Consistent use of stainless steel for superior hygiene

- Pneumatic system for belt tensioning and belt running control

- Open design for thorough cleaning

- Automatic CIP cleaning

Efficiency (TCO)

- Automated operation – one operator suffices

- Low operating and maintenance costs

- Reduced fresh water consumption

- Low energy consumption thanks to efficient drive motor

- Robust design for long life and 24/7 continuous operation

- Continuous work process with high throughflow

Significantly less maintenance effort

Lyckeby Starch, based in southern Sweden, develops and produces potato starch and fibers for the global food and paper industries. Lyckeby is working proactively to manufacture all its products using sustainable processes.

The company uses a Flottweg belt press for dewatering. This video shows why a belt press is used and which advantages the belt press offers compared to screw presses.