- Highest separation performance with over 12,000 g for the finest particles - Made in Germany

- Available in two basic versions: Clarifier (2-phase) & Separator (3-phase)

- Patented Soft Shot® FLEX system for low-noise and efficient solids discharge

Flottweg's disc stack centrifuges epitomize German engineering excellence, offering robust purification and clarification for a diverse range of applications. These separators stand out with their impressive centrifugal accelerations of over 12,000 g, optimizing liquid processing beyond the limits of decanter centrifuges. The innovative disc stack design ensures efficient solids separation and maximized liquid phase purity, while the Soft Shot® discharge system guarantees smooth operation with accurate partial and full discharges in any combination. Flottweg's separators are not only powerful, thanks to their three-phase standard motors and belt drives, but also offer flexible speed regulation and efficient lubrication systems for long-term reliability. Safety is paramount, with all components manufactured to withstand the rigors of high-force operations, ensuring a continuously safe separation process. Tailored to meet specific customer requirements, these separators integrate seamlessly into existing systems, marking them as the final stage in a comprehensive purification process.

Disc centrifuges for clarifying and separating liquids

From algae harvesting to beer clarification and protein extraction: If you want to separate or purify liquids or remove ultra-fine particles you need powerful and robust separators. With their enormous centrifugal acceleration of up to over 12,000 g, Flottweg separators are real purification and clarification all-rounders - highest quality made in Germany.

The right disc separator for your application

Where decanter centrifuges reach their performance limits, separators come into play. Thanks to their higher speeds, they are able to process liquids optimally. Do you want to separate finest solid particles from a liquid? Then a clarifying separator (2-phase separation) is the right solution. Do you need to separate liquid phases of different densities while simultaneously separating solids? Then a purification separator (3-phase separator) is required.

In addition, Flottweg's know-how as a system partner is of great importance, as separators are often the last stage in an extensive separation process. They are often combined with an upstream decanter or Tricanter®. Flottweg customizes the process to the customer's requirements and also finds the best possible separator solution that can be integrated into existing piping and plant systems.

Flottweg disc stack separators are available in two basic designs and are suitable for a wide range of applications:

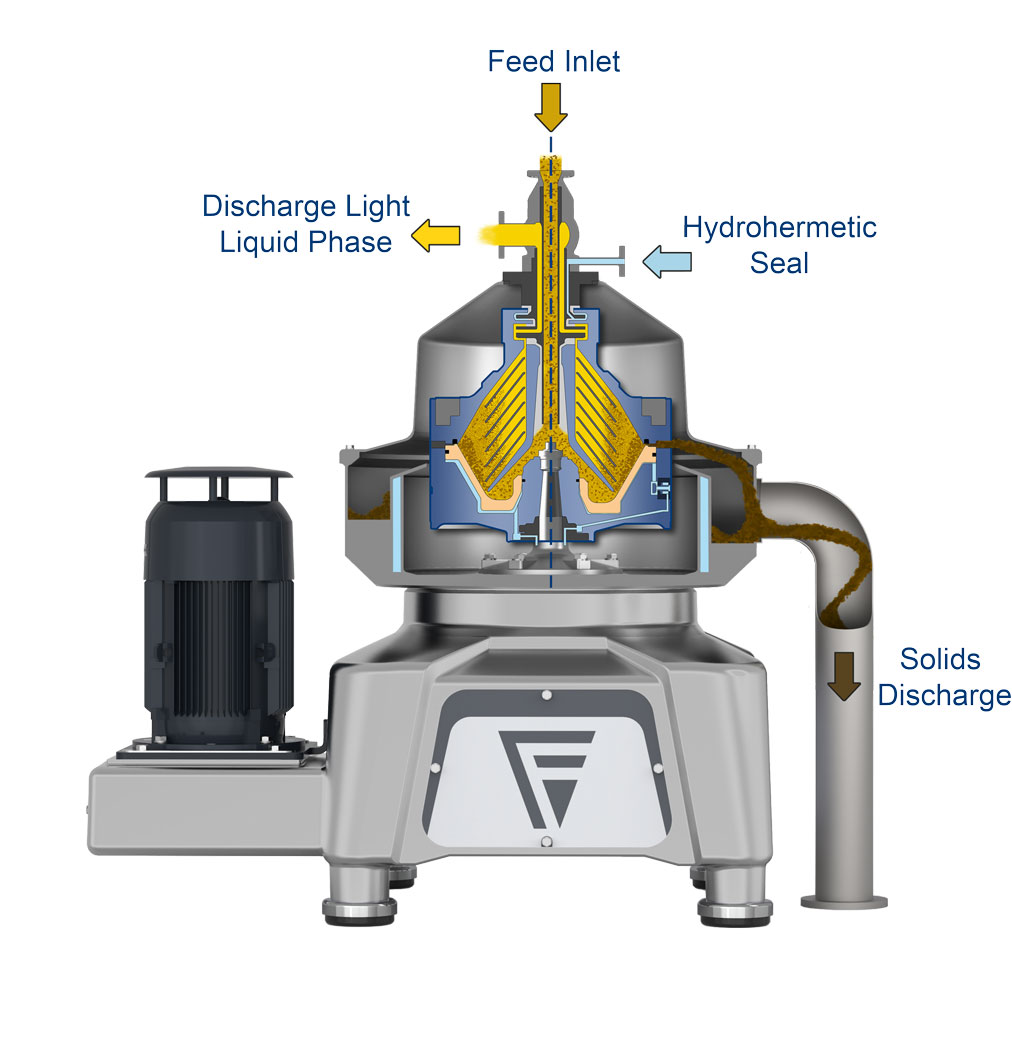

How the Flottweg separator works

The product to be separated flows into the inside of the drum via an infeed pipe.

Inside, a distributor gently accelerates the liquid to full speed.

The product flow is divided into many thin layers in the disk pack. This creates a large separation surface.

Solids are separated from liquids through centrifugal force and separated at the edge of the bowl.

A hydraulic system in the bottom of the bowl periodically discharges the collected solid particles at maximum speed.

A centripetal pump discharges the clarified fluid under pressure.

Flottweg clarifier separator with hydrohermetic seal

Flottweg clarifier separator with hydrohermetic seal

Soft Shot® FLEX

The solids discharge of a Flottweg separator is performed by the patented Flottweg Soft Shot® FLEX discharge system. The system allows a precise and user-defined combination of partial and full emptying. Depending on the products to be processed and the consistency of the solids, the type of discharge can be adjusted to ensure highly efficient operation.

Further information about the system can be found here: Soft Shot® FLEX

Hydrohermetics

The option for 2-phase separators seals the product space from the ambient atmosphere. As a consequence, this feature prevents unwanted oxygen absorption and the formation of foam. The hydrohermetic design of the disk separator consists of a stationary disk which is immersed in a liquid (e.g. degassed water) and thereby creates a seal to the immediate environment.

Further information: Hydrohermetics

Centripetal Pump

The centripetal pump ensures optimum discharge of the clarified liquids from the centrifuge. It discharges the clarified liquid under pressure from the separator bowl and prevents the product from foaming.

Further information: Centripetal Pump

Lubrication system

A lubrication circulation system ensures fully automatic lubrication of the bowl spindle bearings. It lubricates the bearings regularly with an optimum oil quantity. This enables precise and speed-independent lubrication.

Further information: Lubrication system

Disc stack

The actual splitting up of the liquid mixture takes place in the separator bowl disc stack. The disc stack consists of a large number of vertically arranged conical individual discs. The disc stack increases the clarifying area in the separator bowl and thereby the separation efficiency.

Further information on the disc stack can be found here: Disc stack

InGo

The Flottweg separators are controlled by our InGo operating philosophy. It enables optimum interaction of all process components and shows all important process parameters at a glance.

Further information on the user interface can be found here: InGo

Control and automation for Flottweg disc centrifuges

With state-of-the-art automation technology, Flottweg offers complete and intuitive process control. The storage and easy selection of recipes facilitate consistent quality and prevent operating errors:

- Intuitive recipe management: Optimized recipes, selectable with two clicks, save time and ensure consistent results

- Completely automated: Minimizes operator errors and increases process safety

- Plug & Play: Perfect coordination between skid, control system, and machine for a smooth production start

Flottweg Longlife Concept – Consistent design following our simple and smart approach

The Flottweg Longlife Concept maximizes the service life and operational reliability of our separators while keeping operating costs to a minimum. Low-wear components, an automated lubrication system, and extensive monitoring devices ensure reliable long-term operation and reduce maintenance and spare parts costs:

- Inlet system with non-contact seals: Less wear, lower maintenance costs

- Minimal number of wear parts: Lower spare parts costs and thus lower operating costs

- Compact assemblies: Facilitate quick and easy maintenance

- Efficient beltdrive: Highly energy efficiency without additional cooling

- Standard drivemotor: Easily sourced spare parts and uncomplicated repairs are possible

- Safety & Solutions: Monitoring of temperature, speed, and vibration for increased process safety.

- Hygienic design & CIP capability: Hygienic design, fully automatic cleaning.

The Little Atlantique Brewery in Nantes, France uses the AC1700 separator from Flottweg for beer clarification.

Passion for fresh beer, brewing craftsmanship and creativity – this is what the French brewery Little Atlantique in Nantes stands for. Together with the use of a Flottweg separator and the integrated Flottweg recipe control, the brewery has made its processes more efficient and saved costs.