- Flottweg separators with SoftShot® FLEX ensure energy-efficient separation of solids and increase the yield when clarifying beer

- The LongLife Concept minimizes wear and tear, facilitates maintenance and guarantees reliable operation

- Automatic control system using Brewer Control ensures highly consistent product quality that is optimally aligned with the requirements of breweries

Flottweg separators offer a tailor-made solution for breweries striving for the highest quality, efficiency, and sustainability. In the brewing process, they reliably remove yeast and turbidity, resulting in clear beers with consistent flavor. Even before filtration, they significantly extend the filter life and reduce the need for additives such as diatomaceous earth, which lowers costs and makes operations more sustainable. Thanks to precise turbidity settings, breweries can flexibly produce different beer styles, from naturally cloudy wheat beer to crystal-clear lager beers. In addition, the separators optimize the fermentation and maturation process by ensuring constant yeast counts in young beer, which enables consistently high product quality. With their energy-efficient technology and the ability to reduce beer loss and wastewater streams, Flottweg separators are a forward-looking investment for breweries of all sizes that want to combine quality, economy, and sustainability.

Preventing hops and malt from going to waste: Efficient beer separation for maximum yield and flexibility

Customized centrifuge systems – to meet the requirements of beer clarification and cold processes in modern breweriesBeer clarification is an essential step in the brewing process that does more than just remove turbidity. It ensures the purity, characteristic flavor, and long shelf life of the beer by effectively removing unwanted suspended matter, such as yeast cells, proteins, hop residues, and starch.

For large-scale production, both quality and efficiency are decisive criteria. Flottweg offers modern separation technologies that facilitate a faster and more effective separation than is possible with sedimentation. This minimizes losses, maximizes yield, and makes optimal use of storage tank capacity, thus saving costs.

Flottweg separators feature a fully automatic monitoring and control system, ensuring consistent quality and high process reliability throughout large-scale production. They relieve the load on the filtration system, reduce the consumption of filter aids, and reduce maintenance and cleaning requirements – all these factors are important for achieving cost-effectiveness. Flottweg separators offer flexible solutions for both craft and medium-sized breweries, facilitating precise clarification of various beer styles, from naturally cloudy to crystal clear. This allows brewers to respond to market demands and consumer trends without compromising on taste and quality. Flottweg supports breweries of all sizes in their efforts to efficiently produce high-quality, sustainable beer.

Centrifuges for Beer Clarification and Production

Challenges in beer filtration

Beer filtration presents significant challenges to breweries, particularly when the beer contains a high concentration of yeast, as this restricts the time it can be left to stand during kieselguhr filtration.

Uneven sedimentation in wheat beers and naturally cloudy beers often leads to fluctuations in turbidity. Additionally, brewers must strike a balance between clarity and taste. Many beer drinkers appreciate the natural turbidity of beer and its more intense aroma.

Improving filtration without unnecessarily shortening the service life of the filters or increasing operating costs requires the right choice of filter aid, such as Kieselguhr.

Another problem is oxygen absorption during filtration, which can negatively affect taste and shelf life.

Innovative technologies, such as Flottweg separators, also help to compensate for fluctuations in turbidity and ensure a constant quality. All in all, the process of beer filtration requires the precise coordination of various factors, technical expertise and modern equipment. Only then can a visually appealing beer with a pleasing taste be produced economically.

Flottweg separator at the Kuchlbauer brewery

The Brewing Process with Flottweg Separation Technology

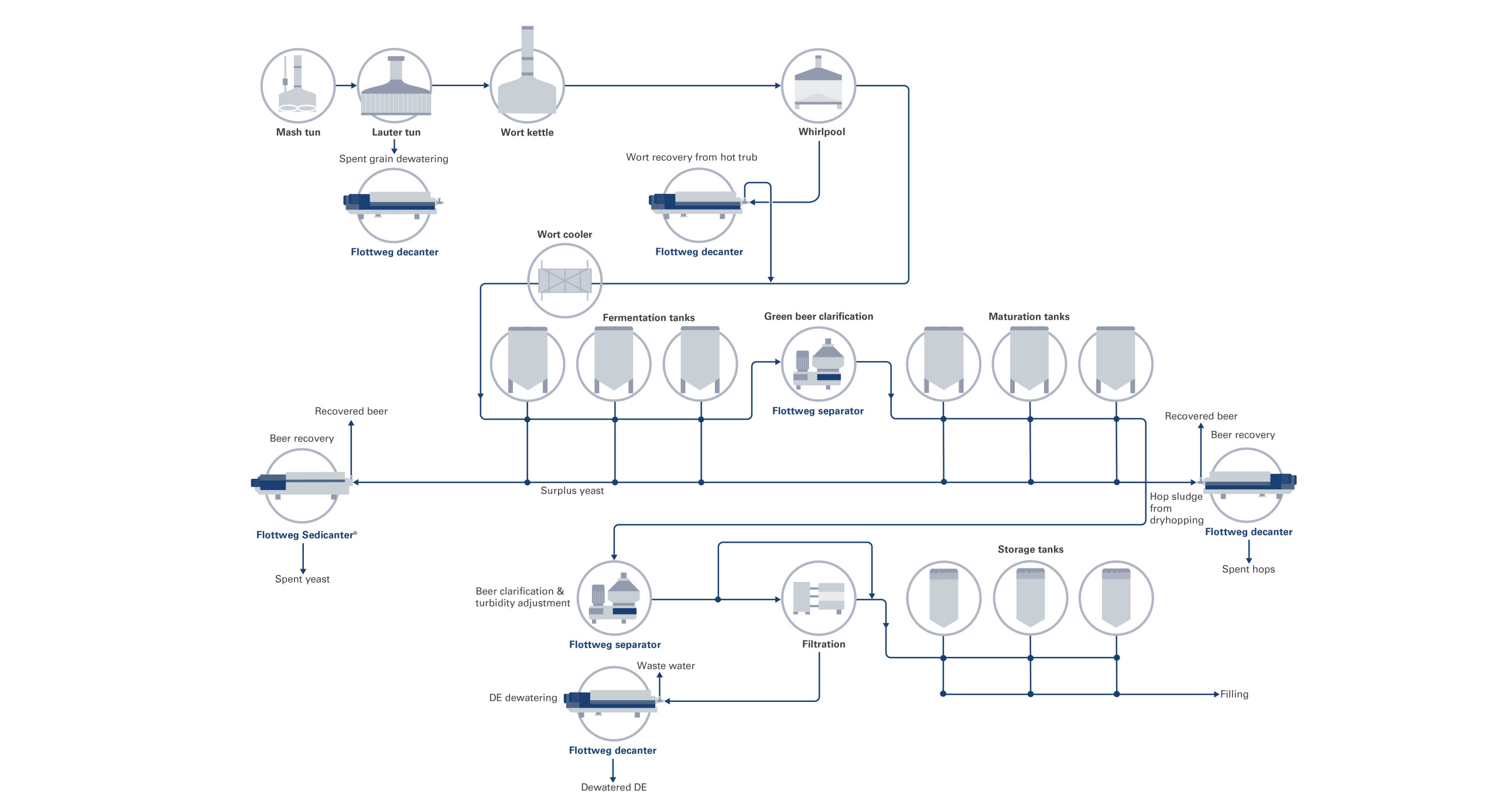

Transforming grains into refreshing beer involves a complex process. Beer, in its many forms during production, is created step-by-step in the brewery’s hot and cold processes. Flottweg’s highly efficient beer centrifuges meet the specific requirements of breweries while optimizing the entire process for maximum yields with the utmost level of quality.

More than just beer is produced in the brewing process: Brewers grains, surplus yeast, and spent hops are all by-products that no longer play a role in the production of beer. There are also wastewater flows, such as Kieselguhr, which is a form of diatomaceous earth used in manufacturing. When these waste materials are not handled directly by the breweries, they must also be sold or disposed, which leads to wastewater, disposal, and transport costs.

With its decanters and Sedicanter®, Flottweg offers proven technologies for increasing the efficiency of the brewing process: The decanter separates over 98% of the liquid wort from the hot trub, thus reducing losses. The Sedicanter®, on the other hand, is particularly useful for the recovery of beer from fermentation and bottom-fermenting yeasts; it separates solids in cold processes with over 99% efficiency. The Flottweg separator, of course, is the heart of the beer clarification process. It is primarily used in the later stages of the brewing process to gently and effectively remove yeast cells, hop residues, and other clouding agents. The carbon dioxide remains in the beer thanks to the pressurized discharge and the hydrohermetic seal.

The separator also extends the life of filters and minimizes beer losses. It ensures consistent turbidity, particularly for wheat and naturally turbid beers, and gives breweries the flexibility to manufacture different beer styles to the highest quality standards.

With many decades of experience in separation technology, Flottweg finds custom and comprehensive solutions for specific brewing processes. The equipment can be smoothly integrated into everyday operations and adapted to the hygiene control requirements of breweries.

The Flottweg separator: Clear results

Clarification for medium-sized and craft beer breweries

The separator offers maximum efficiency without having to rely on a traditional downstream filter. The turbidity adjustment allows brewers to creatively and precisely make different styles of beer – from naturally cloudy all the way to clear, crisp lager beer. This flexibility makes it easier than ever to cover a wide range of different beers while simultaneously responding quickly to trends and consumer demands. The use of the separator increases the yield and reduces beer loss, since it ensures reliable clarification. This enables breweries to operate efficiently and sustainably.

Prolonged filter life

The separator removes most of the yeast from the beer before filtration. As a result, the service life of the filter can be extended. In addition, less kieselguhr is required, which reduces the procurement, handling, and disposal costs associated with the filter.

Green beer clarification for optimal fermentation

By adjusting yeast cell counts in green beer, our separators keep conditions constant during post-fermentation and maturation. Improving the post-fermentation process in this way results in a consistent beer quality.

Our separators can also be used to produce alcohol-free beers, depending on the process, e.g., when fermentation is stopped.

Adjusting the turbidity for wheat beer and naturally cloudy beer

Unequal sedimentation is a major challenge when storing wheat beer and naturally cloudy beer. However, Flottweg separators are an elegant solution for balancing these yeast fluctuations. The brewer only has to specify the turbidity value of the finished beer – the rest is done automatically.

SoftShot® FLEX

- More beer through higher yield

- Efficient solids separation of typically 22-24% dry matter content

- Optimal and flexible adaptation to different beer styles

- Energy efficient

Minimal sound level

- Minimal noise: The quietest system on the market

- Water Damped System: Less noise and wear

- Safe and comfortable working environment

Brewer Control

- Consistent product quality

- Clear display of all relevant process parameters

- Easy recipe management and fully automated process control

- User interface tailored to the brewer's needs

LongLife Concept

- Designed for maximum life and minimum wear

- Fast and easy access to all components

- Reduced operating costs

- Increased reliability

Sustainability and cost reduction with beer centrifuges

Integrating beer centrifuges into the brewing process enhances quality while reducing the consumption of resources. The use of fewer filter aids, such as Kieselguhr, reduces both waste and the associated impact on the environment. In addition, precise separation facilitates lower water consumption by reducing the need for cleaning.

Breweries benefit from a longer filter service life and a reduced need for filtering aids, both of which reduce costs. Gentle solids discharge minimizes beer losses and optimizes raw material consumption. Modern separators are energy efficient and consume less electricity.

The automated operation of beer centrifuges ensures smooth operation, increases productivity and strengthens competitiveness.

The Little Atlantique Brewery in Nantes, France uses the AC1700 separator from Flottweg for beer clarification.

Passion for fresh beer, brewing craftsmanship and creativity – this is what the French brewery Little Atlantique in Nantes stands for. Together with the use of a Flottweg separator and the integrated Flottweg recipe control, the brewery has made its processes more efficient and saved costs.

Beer clarification as a success factor for modern breweries

Beer clarification is much more than just a simple cleaning step within the brewing process. It not only ensures that the beer is visually clear and appealing, but also that it tastes good and has a long shelf life. ionThe flexibility and precision of clarification technology are of particular importance in modern breweries that produce a wide array of beer types. Different beer styles require varying degrees of clarification - from cloudy to crystal clear - and this is precisely where Flottweg's innovative separators offer the perfect solution.

Overall, the use of Flottweg separators for modern beer clarification is essential for breweries that prioritize quality, efficiency and sustainability. It optimizes the brewing process, saves valuable resources and ensures that the final product meets the highest standards.

Benefiting every Flottweg customer

Decades of experience

Flottweg has been passionate about manufacturing centrifuges for solid/liquid separation for over 70 years. With Made in Germany quality, our worldwide customers are always impressed by our expertise.

Individual advising

Our sales team is always happy to provide you with personalized advice. We look at your individual process to guarantee your success.

Dependable service

Even the best machine needs servicing from time to time. We have subsidiaries and representatives standing by around the world to hear your concerns. We are happy to advise you, whenever you need us.

Long-lasting durability

Flottweg machines can be operated day and night for years because they are made of high-quality materials, equipped with numerous practical features, and use technology that sets the global standard.