- Customized separation solutions for maximum yield and optimal beer clarification

- Flottweg Beer centrifuges meet specific requirements and can be easily integrated into ongoing operations

- Many years of brewing expertise with worldwide service and CIP-ready systems

Keeping Hops and Malt from Ever Being Wasted

Indespensable, from start to finish - Industrial centrifuges for beer clarification and productionThe clarification and separation steps in the brewing process are important for removing impurities and turbidity from the beer. The art of brewing has always focused around purity, cost effectiveness, and, ultimately, taste and aroma. Our customers combine all of these aspects using state-of-the-art separation technology by Flottweg.

Centrifuges for Beer Clarification and Production

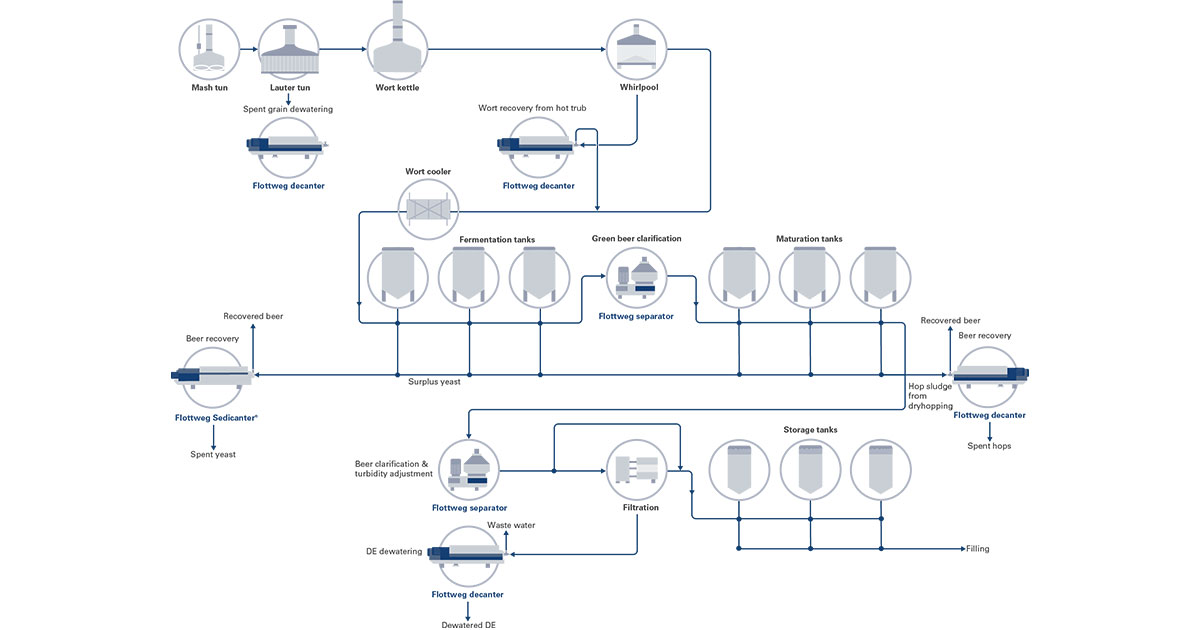

The Brewing Process with Flottweg Separation Technology

Transforming grains into refreshing beer involves a complex process. Beer, in its many forms during production, is created step-by-step in the brewery’s hot and cold processes. Flottweg’s highly efficient beer centrifuges meet the specific requirements of breweries while optimizing the entire process for maximum yields with the utmost level of quality.

More than just beer is produced in the brewing process: Brewers grains, surplus yeast, and spent hops are all by-products that no longer play a role in the production of beer. There are also wastewater flows, such as Kieselguhr, which is a form of diatomaceous earth used in manufacturing. When these waste materials are not handled directly by the breweries, they must also be sold or disposed, which leads to wastewater, disposal, and transport costs. Additionally, valuable wort and beer contained in the separated by-product are lost.

Efficient mechanical dewatering is made possible by the Flottweg belt press, which separates liquid components from the spent brewers grains. The separated solids are well suited for further processing due to their very high dry substance content. This turns what would be waste from breweries into valuable resources.

Flottweg decanters, Sedicanters®, and separators increase brewing process efficiency: The Flottweg decanter separates up to 75% liquid wort from the separated hot trub and returns it to the brewing process. The same is also true for dry-hopped beers: when the decanter is used in the cold process to separate the spent hops, it will reduce wort and beer losses. The Sedicanter® is an extremely effective centrifuge assembly that recovers beer from top and bottom fermenting yeast. Flottweg separators are mostly used in the advanced stages of the brewing process. They optimize the fermentation and filtration process or are directly responsible for the final clarification of the beer.

With many decades of experience in separation technology, Flottweg finds custom and comprehensive solutions for specific brewing processes. The equipment can be smoothly integrated into everyday operations and adapted to the hygiene control requirements of breweries. The straightforward and robust design of all production lines ensure easy operation and maintenance. The basis for this, among other things, is the high-quality, wear-resistant components that Flottweg develops and manufactures entirely in Germany.

Beer clarification

Beer filtration is one of the biggest challenges for brewers. Flottweg recognizes this and has optimized its separators accordingly.

Flexible and reliable clarification for medium-sized and craft beer breweries

The separator offers maximum efficiency without having to rely on a traditional downstream filter. The turbidity adjustment allows brewers to creatively and precisely make different styles of beer – from naturally cloudy all the way to clear, crisp lager beer. This flexibility makes it easier than ever to cover a wide range of different beers while simultaneously responding quickly to trends and consumer demands. The use of the separator increases the yield and reduces beer loss, since it ensures reliable clarification. This enables breweries to operate efficiently and sustainably.

Prolonged filter life

The separator removes most of the yeast from the beer before filtration. As a result, the service life of the filter can be extended. In addition, less kieselguhr is required, which reduces the procurement, handling, and disposal costs associated with the filter.

Green beer clarification for optimal fermentation

By adjusting yeast cell counts in green beer, our separators keep conditions constant during post-fermentation and maturation. Improving the post-fermentation process in this way results in a consistent beer quality.

Our separators can also be used to produce alcohol-free beers, depending on the process, e.g., when fermentation is stopped.

Adjusting the turbidity for wheat beer and naturally cloudy beer

Unequal sedimentation is a major challenge when storing wheat beer and naturally cloudy beer. However, Flottweg separators are an elegant solution for balancing these yeast fluctuations. The brewer only has to specify the turbidity value of the finished beer – the rest is done automatically.

SoftShot® FLEX

- More beer through higher yield

- Efficient solids separation of typically 22-24% dry matter content

- Optimal and flexible adaptation to different beer styles

- Energy efficient

Minimal sound level

- Minimal noise: The quietest system on the market

- Water Damped System: Less noise and wear

- Safe and comfortable working environment

Brewer Control

- Consistent product quality

- Clear display of all relevant process parameters

- Easy recipe management and fully automated process control

- User interface tailored to the brewer's needs

LongLife Concept

- Designed for maximum life and minimum wear

- Fast and easy access to all components

- Reduced operating costs

- Increased reliability

In recent years, dry hopping has gone from being a trend, especially popular with up-and-coming craft breweries, to an established technique within the entire brewing industry. If you ask 100 brewers when they add the hops, you will get 100 different responses. We are always happy to give you the information you need to brew how you want in spite of modernization and the use of newer technology.

For craft brewers in particular, the character of their beer is very important. A small change to the taste of the beer can result in a completely different aroma. Unlike industrial breweries, a craft brewery often has less space and production capacity, making it all the more important to get the most out of their existing resources.

After extraction, the dissolved hop pellets sediment at the bottom of the maturation tanks as tank bottoms and are traditionally discharged to protect downstream processes. In this process, not only hop residues but also a considerable volume of fresh beer ends up in the drain, leading to unnecessary product loss.

Flottweg decanters separate hop residue from high-grade beer and return this beer to the storage and production process. This improves the yield while also decreasing the amount of wastewater.

All the benefits, at a glance:

- Significant reduction in beer loss

- Up to 99% particle separation

- Less load on centrifuges and beer filters

- Reduced wastewater load

- Fully automatable

- Additional beer recovery from yeast sediment or from alternative flavor carriers (herbs, fruits, peanut butter, coffee)

Advanced hop-beer separation

Up to 99% of hop particle removal for recovered beer that's clean, fresh and full of flavor.

High yield

With precise centrifuge adjustments for various hop quantities or recipes, up to 97% of the beer volume is recovered, while achieving excellent dewatering of hop solids and a dry, free-flowing discharge.

Minimized oxygen pickup

Beer discharge under pressure, protected by CO2 blanketing.

Plug & Play system

Flottweg's pioneering process, proven and trusted by craft and large-scale breweries worldwide.

The best way to significantly reduce beer evaporation is to recover beer from surplus yeast after fermentation or maturation.

Like the old German saying, we follow the motto "preventing the hops and malt from being lost" to generate two valuable products from yeast recovery. First there is the beer, which can be returned to the process, then there is the yeast. This yeast can be sold, for example, to be processed further within the food industry as a vitamin-rich nutritional supplement or animal feed.

Simple process, highest quality, lower costs – the Flottweg Sedicanter®

This system handles the beer being processed with utmost care. In addition, it can also easily process fluctuating concentrations of input yeast.

All the benefits, at a glance:

- Reduced beer evaporation

- Careful processing of beer

- Yeast cake with high dry solids content

- Less wastewater

- Easy to integrate into existing processes

Highest-quality workmanship

- Machine design specifically adapted to high hygienic requirements of breweries

- Easy integration into brewery’s CIP system

Safe and careful processing

Clever design for consistent product quality

Separating wort, hop debris, and precipitated protein causes hot trub to form in the whirlpool. This hot trub still contains up to 75% wort. To prevent this wort from being lost, our customers rely on Flottweg decanters.

Our decanter first separates the trub from the wort, then returns it to the hot wort clarification process under pressure. This both reduces the production cost per hectoliter of beer and minimizes wort loss.

And we haven't even mentioned the extras offered by Flottweg, not the competition – unique features we have developed in-house. These include the Simp Drive® system, which has been in use for many years. This drive automatically regulates the differential speed according to the scroll torque. This enables operators to adapt to different load conditions and maximize their yield.

All the benefits, at a glance:

- Significant reduction in wort loss

- Lower production costs per hectoliter of beer

- Automatic control for optimal yield

Clear wort

- Adjustable impeller for seamless conversion to the requirements of different recipes and hot trubs

- Clarified wort is discharged under pressure

Optimal process management

- Continuous, automatic operation

- Shorter hold time in whirlpool

When it comes to creating a valuable material from unwanted byproducts, both the ecological aspect of upcycling as well as economic efficiency play a role.

The brewers grain produced during beer production often still contains a high proportion of nutrients and protein. This product can be used, for example, as animal feed or as a nutritional supplement. However, it is necessary to dewater the brewers grain as much as possible.

This is where Flottweg technology comes into play: A decanter can be used to dewater the brewers grain up to a dry solids content of 40 percent.

Dewatering decreases the volume, lowering the costs of disposal and transport. Mechanical dewatering is the basis for further thermal drying processes that turn brewers grain into a valuable product that can be stored and used. The more efficient the decanter process is, the lower the resulting costs of the drying step are.

Nowadays, beer recovery is no longer just about beer. Valuable and nutrient-rich, yeast has made its way into the food industry as a nutritional supplement and protein source. The Flottweg Sedicanter® is perfect for these applications, since thick yeast can only be dewatered effectively when high g-forces are used. The yeast is separated selectively, forming a dewatered cake to prevent it from being lost.

Upcycling

The process of turning waste into recyclable material makes it possible to act sustainably and take responsibility for people and nature. Deliberately reducing CO2 emissions is becoming increasingly important for industry, as transforming a waste product into another useful product has a positive effect on CO2 balance.

Cost saving

Economic efficiency and cost reduction now play a decisive role in the management of companies of all sizes. Flottweg decanters are the perfect solution for saving resources during disposal and transport.

Benefiting every Flottweg customer

Decades of experience

Flottweg has been passionate about manufacturing centrifuges for solid/liquid separation for over 70 years. With Made in Germany quality, our worldwide customers are always impressed by our expertise.

Individual advising

Our sales team is always happy to provide you with personalized advice. We look at your individual process to guarantee your success.

Dependable service

Even the best machine needs servicing from time to time. We have subsidiaries and representatives standing by around the world to hear your concerns. We are happy to advise you, whenever you need us.

Long-lasting durability

Flottweg machines can be operated day and night for years because they are made of high-quality materials, equipped with numerous practical features, and use technology that sets the global standard.

For All Tastes

The Rhinegeist-Brauerei in Ohio brews more than 90 types of beer with great passion and creativity. There is something here for every taste. The beers run through the Flottweg separator during clarification.

It continuously removes different amounts of yeast and hops – to the great satisfaction of the brewmasters, as this video shows.